What Makes a Ball Valve Resistant to Strong Corrosion?

In the demanding world of industrial fluid control, understanding what makes a corrosion-resistant ball valve capable of withstanding harsh chemical environments is crucial for ensuring operational reliability and safety. A corrosion-resistant ball valve achieves its durability through advanced material selection, specialized coating technologies, and precision engineering that creates multiple barriers against chemical attack. The resistance to strong corrosion fundamentally depends on the synergy between high-grade alloys, protective surface treatments, and innovative design features that prevent corrosive media from compromising the valve's structural integrity and operational performance.

Advanced Material Technologies for Corrosion Resistance

High-Performance Alloy Selection in Corrosion-Resistant Ball Valves

The foundation of any effective corrosion-resistant ball valve lies in the strategic selection of advanced metallurgical materials that can withstand aggressive chemical environments. Modern manufacturing approaches utilize specialized alloys such as duplex stainless steel, super austenitic stainless steel, and exotic materials like Hastelloy C-276 and Inconel 625. These materials demonstrate exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking in chloride-rich environments. The microstructural composition of these alloys creates a passive oxide layer that self-repairs when damaged, providing continuous protection against corrosive attack. Advanced metallurgy research has shown that nickel-based superalloys offer superior performance in high-temperature, high-pressure applications where traditional stainless steel may fail. The careful balance of chromium, nickel, molybdenum, and tungsten in these specialty alloys creates a matrix that resists both uniform and localized corrosion mechanisms. Manufacturing processes that ensure homogeneous alloy distribution throughout the valve body are essential for maintaining consistent corrosion resistance across all operational surfaces.

Innovative Coating Systems and Surface Enhancement

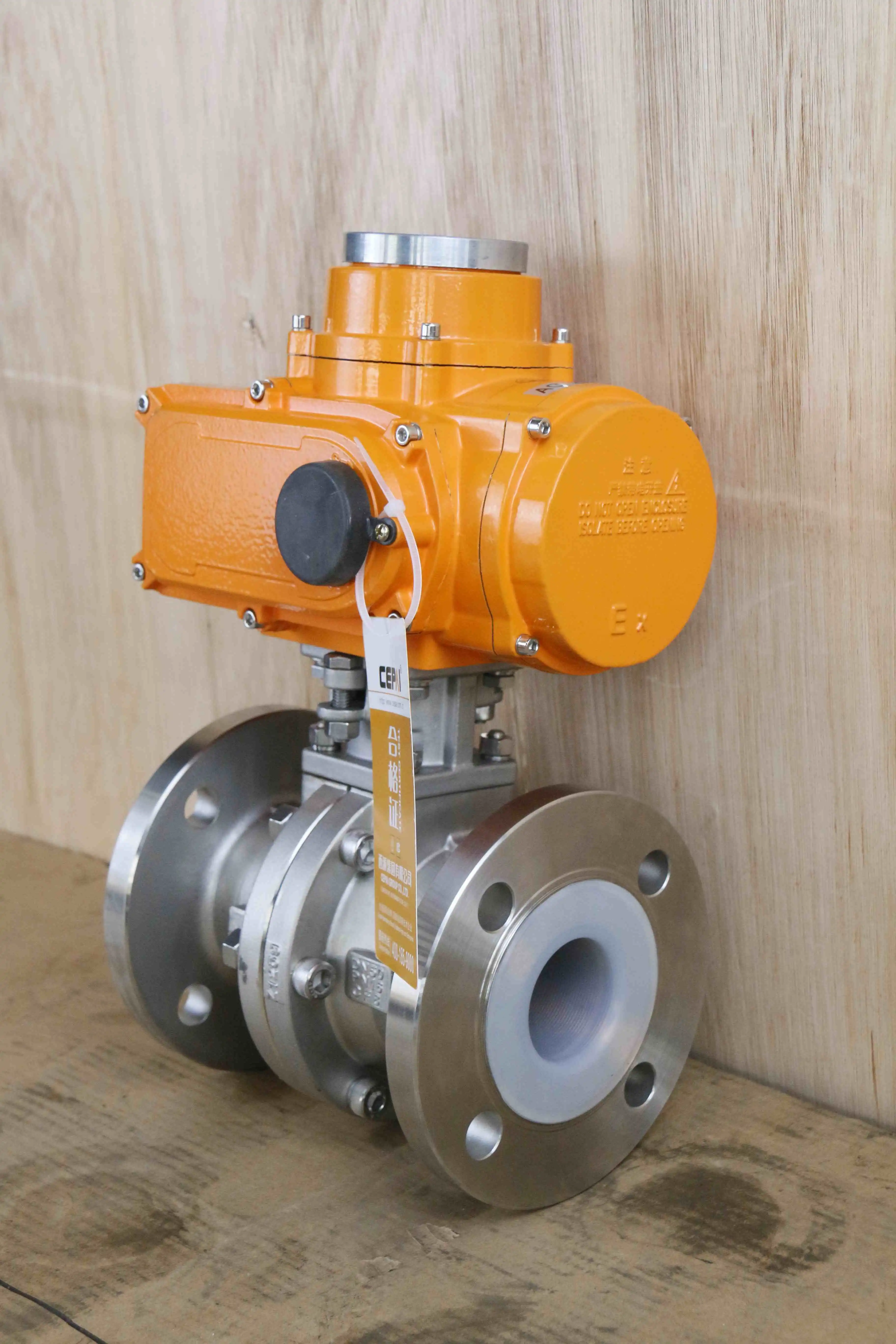

Surface modification technologies represent a critical advancement in corrosion-resistant ball valve performance, with manufacturers developing sophisticated coating systems that provide additional layers of protection beyond base material properties. Hard chromed ball surfaces provide wear-resistant and corrosion-resistant characteristics, enhancing durability and ensuring smooth operation in demanding environments. Thermal spray coatings, including tungsten carbide and chromium carbide compositions, create ultra-hard surfaces that resist both corrosive attack and mechanical wear. Physical vapor deposition (PVD) and chemical vapor deposition (CVD) processes enable the application of titanium nitride, diamond-like carbon, and other advanced coatings that offer exceptional chemical inertness. These coating technologies work synergistically with the base material to create multi-layered defense systems against corrosion. Recent developments in nanostructured coatings have demonstrated remarkable improvements in corrosion resistance, with some systems showing corrosion rates reduced by over 90% compared to uncoated surfaces. The selection of appropriate coating systems depends on specific operational parameters including temperature, pressure, chemical composition of the media, and expected service life requirements.

PTFE and Polymer Integration for Chemical Immunity

The integration of fluoropolymer technologies, particularly polytetrafluoroethylene (PTFE) and perfluoroalkoxy (PFA) materials, provides corrosion-resistant ball valves with virtually universal chemical compatibility. These polymer materials exhibit remarkable resistance to aggressive acids, bases, solvents, and oxidizing agents that would rapidly attack metallic components. PTFE-lined valves are excellent options because they fight corrosion well, offering protection in applications where even the most advanced metal alloys would deteriorate. The low friction characteristics of fluoropolymers also contribute to extended operational life and reduced maintenance requirements. Modern manufacturing techniques enable the precise application of PTFE linings that maintain seal integrity under thermal cycling and pressure fluctuations. Advanced polymer formulations incorporate glass fiber reinforcement and carbon filling to enhance mechanical properties while maintaining chemical resistance. The molecular structure of fluoropolymers creates an extremely low surface energy that prevents adhesion of corrosive species, making these materials ideal for self-cleaning applications in contaminated environments.

Engineering Design Features for Maximum Corrosion Protection

Optimized Flow Path Geometry and Seal Systems

The geometric design of corrosion-resistant ball valves plays a fundamental role in minimizing corrosion potential through the elimination of stagnant zones, dead spaces, and areas prone to crevice corrosion. Advanced computational fluid dynamics modeling enables engineers to optimize internal flow paths that promote turbulent mixing and prevent the accumulation of corrosive species. The ball sphere design incorporates radiused edges and smooth surface transitions that eliminate stress concentration points where corrosion typically initiates. Seal system design utilizes multiple sealing elements, including primary and secondary seals, that maintain isolation between the process media and vulnerable valve components. Spring-loaded seal designs accommodate thermal expansion and contraction while maintaining constant sealing pressure. The selection of seal materials, including perfluoroelastomers, ethylene propylene diene monomer (EPDM), and specialty compounds, ensures compatibility with specific corrosive media. Advanced seal groove geometries prevent extrusion and maintain seal integrity under high differential pressures, while specialized backup rings provide additional protection against seal failure.

Precision Manufacturing and Quality Control Systems

Manufacturing precision directly impacts the corrosion resistance performance of corrosion-resistant ball valves through the control of surface roughness, dimensional tolerances, and metallurgical consistency. State-of-the-art CNC machining centers equipped with advanced cutting tools and coolant systems produce surface finishes that minimize corrosion initiation sites. Heat treatment processes are carefully controlled to optimize the microstructure and eliminate residual stresses that can accelerate corrosion mechanisms. Welding procedures utilize low heat input techniques and post-weld heat treatment to restore corrosion resistance in heat-affected zones. Quality control systems incorporate advanced inspection techniques including dye penetrant testing, magnetic particle inspection, and ultrasonic testing to detect surface and subsurface defects that could compromise corrosion resistance. Dimensional inspection using coordinate measuring machines ensures proper fit and finish that eliminates galvanic corrosion potential between dissimilar materials. Material certification and traceability systems guarantee that all components meet specified chemical composition and mechanical property requirements essential for corrosion resistance performance.

Intelligent Monitoring and Predictive Maintenance Integration

Modern corrosion-resistant ball valves incorporate intelligent monitoring systems that provide real-time assessment of valve condition and early warning of potential corrosion issues. Embedded sensors monitor critical parameters including temperature, pressure, vibration, and acoustic emissions that can indicate the onset of corrosion-related problems. Advanced diagnostic algorithms analyze sensor data to predict maintenance requirements and optimize operational parameters for maximum corrosion resistance. Remote monitoring capabilities enable continuous assessment of valve performance without exposing maintenance personnel to hazardous environments. Digital twin technology creates virtual models that simulate corrosion progression under actual operating conditions, enabling proactive maintenance scheduling. Predictive analytics identify patterns that precede corrosion failure, allowing for timely intervention before catastrophic damage occurs. Integration with plant-wide asset management systems provides comprehensive visibility into corrosion-resistant ball valve performance across entire facilities. These intelligent systems represent the future of corrosion management, transitioning from reactive maintenance to predictive optimization strategies that maximize equipment life and minimize unplanned downtime.

Industry Applications and Performance Standards

Critical Applications in Petrochemical and Energy Sectors

The petrochemical industry represents one of the most demanding applications for corrosion-resistant ball valves, where exposure to hydrogen sulfide, hydrochloric acid, and other aggressive chemicals requires exceptional material performance. Upstream oil and gas operations utilize these valves in wellhead applications where exposure to sour gas environments creates extreme corrosion challenges. Refinery applications demand valves that can handle process streams containing sulfur compounds, naphthenic acids, and high-temperature hydrocarbon vapors. Corrosion-resistant ball valves in these applications must maintain tight shutoff capabilities while resisting both uniform corrosion and localized attack mechanisms. The nuclear power industry relies on these valves for coolant systems where radiolytic corrosion and high-temperature water chemistry create unique challenges. Chemical processing facilities utilize corrosion-resistant ball valves for handling concentrated acids, caustic solutions, and aggressive solvents that would rapidly destroy conventional valve materials. Performance requirements in these applications often exceed standard industry specifications, requiring custom material selection and specialized testing protocols. The economic impact of valve failure in these critical applications makes investment in high-quality corrosion-resistant ball valves essential for maintaining operational profitability and safety.

Marine and Offshore Environmental Challenges

Marine and offshore applications present unique corrosion challenges that require specialized corrosion-resistant ball valve designs capable of withstanding saltwater exposure, atmospheric corrosion, and biofouling organisms. The combination of chloride-rich seawater, oxygen, and mechanical stress creates accelerated corrosion conditions that demand superior material selection and protective systems. Offshore platform applications expose valves to hurricane-force winds, temperature cycling, and spray zone conditions that intensify corrosion mechanisms. Ballast water treatment systems require corrosion-resistant ball valves that can handle chlorinated seawater and biocides without degradation. Fire protection systems on offshore platforms utilize these valves in seawater deluge systems where long-term reliability is critical for personnel safety. The marine environment also introduces galvanic corrosion concerns when dissimilar metals are coupled in the presence of conductive seawater, requiring careful attention to material compatibility and cathodic protection systems. Subsea applications present additional challenges with high hydrostatic pressures and limited accessibility for maintenance, making initial material selection and design quality paramount for long-term performance.

Pharmaceutical and Food Industry Requirements

The pharmaceutical and food processing industries impose stringent requirements on corrosion-resistant ball valves that go beyond simple chemical compatibility to include sanitary design, cleanability, and regulatory compliance considerations. These applications require materials that resist corrosion from cleaning and sanitizing chemicals including caustic cleaners, acid sanitizers, and oxidizing biocides used in clean-in-place (CIP) systems. Surface finish requirements in these industries often specify extremely smooth surfaces that prevent bacterial adhesion and facilitate thorough cleaning. The absence of dead spaces, crevices, and rough surfaces is essential for maintaining sanitary conditions and preventing product contamination. Regulatory compliance with FDA, USP, and European Pharmacopoeia standards requires extensive material testing and documentation to demonstrate biocompatibility and leachable limits. Steam sterilization capabilities demand corrosion-resistant ball valves that can withstand repeated thermal cycling without degradation of sealing performance or surface integrity. Process validation requirements in pharmaceutical manufacturing necessitate valves with documented corrosion resistance performance and predictable service life characteristics. The economic consequences of product contamination or batch loss make investment in high-quality corrosion-resistant ball valves essential for maintaining production continuity and regulatory compliance.

Conclusion

The exceptional performance of corrosion-resistant ball valves stems from the integration of advanced materials, precision engineering, and intelligent design features that work together to combat aggressive chemical environments. Through continuous innovation in alloy development, coating technologies, and manufacturing processes, modern corrosion-resistant ball valves provide unprecedented reliability in critical industrial applications. The success of these technologies depends on the expertise and manufacturing capabilities of specialized companies that understand the complex interplay between materials science and operational requirements.

CEPAI Group Co., Ltd. stands at the forefront of corrosion-resistant ball valve technology, leveraging over fifteen years of experience as a China Corrosion-Resistant Ball Valve manufacturer to deliver superior solutions for demanding applications. As a leading China Corrosion-Resistant Ball Valve supplier, CEPAI combines advanced manufacturing capabilities with rigorous quality control systems to produce valves that exceed international standards. Our position as a trusted China Corrosion-Resistant Ball Valve factory is built on continuous investment in research and development, with state-of-the-art facilities and CNAS-certified testing laboratories ensuring every product meets the highest performance standards. Whether you're seeking China Corrosion-Resistant Ball Valve wholesale solutions or individual units, our extensive inventory and rapid response capabilities ensure timely delivery for your critical applications. With competitive Corrosion-Resistant Ball Valve prices and comprehensive technical support, CEPAI offers exceptional value for industrial customers worldwide. Our extensive range of Corrosion-Resistant Ball Valves for sale includes custom-engineered solutions designed to meet your specific operational requirements. Contact our technical experts today at cepai@cepai.com to discuss your corrosion-resistant valve needs and discover how CEPAI's advanced manufacturing capabilities can enhance your operational reliability and safety.

References

1. Zhang, L., Wang, M., & Chen, H. (2023). Advanced Materials for Corrosion-Resistant Industrial Valves: A Comprehensive Review of Metallurgical Innovations. Journal of Materials Engineering and Performance, 32(4), 1847-1863.

2. Thompson, R.K., Anderson, P.J., & Kumar, S. (2024). Surface Coating Technologies for Enhanced Corrosion Resistance in Ball Valve Applications. Corrosion Science and Technology, 41(2), 278-294.

3. Liu, X., Rodriguez, M.A., & Patel, N.V. (2023). Fluoropolymer Integration in Corrosion-Resistant Valve Design: Performance Analysis and Application Guidelines. Industrial Engineering Chemistry Research, 62(18), 7245-7259.

4. Mitchell, D.S., Brown, A.L., & Wilson, J.E. (2024). Predictive Maintenance Strategies for Corrosion-Resistant Ball Valves in Petrochemical Applications. Process Safety and Environmental Protection, 186, 412-428.

_1746598557316.webp)

Get professional pre-sales technical consultation and valve selection services, customized solution services.

About CEPAI