Top 5 Benefits of Using Pneumatic Ball Valves in Automated Systems

When automated systems fail due to inefficient flow control, production lines grind to a halt, costing companies millions in downtime and lost productivity. The solution lies in understanding how Pneumatic Ball Valve technology revolutionizes industrial automation by delivering unmatched precision, reliability, and efficiency. This comprehensive guide explores the top 5 transformative benefits that make Pneumatic Ball Valve systems essential for modern automated operations, providing you with the knowledge to optimize your industrial processes and eliminate costly operational disruptions.

Enhanced Precision and Control in Automated Operations

-

Superior Flow Control Accuracy

Modern industrial automation demands exceptional precision, and Pneumatic Ball Valve systems deliver precisely that level of control required for complex manufacturing processes. These advanced valve systems utilize compressed air to provide instantaneous response times, allowing operators to achieve flow control accuracy within tight tolerances that manual systems simply cannot match. The quarter-turn operation characteristic of ball valve design combined with pneumatic actuation creates a reliable control mechanism that maintains consistent performance across varying operational conditions. The precision offered by Pneumatic Ball Valve technology becomes particularly critical in applications where even minor deviations in flow rates can result in product defects or safety concerns. Industries such as pharmaceutical manufacturing, food processing, and chemical production rely heavily on this precise control to maintain product quality standards and regulatory compliance. The ability to achieve repeatable positioning accuracy ensures that automated systems can deliver consistent results, reducing variability in production outputs and minimizing waste generation.

-

Real-Time Response Capabilities

Pneumatic actuated ball valves provide exceptional response times that are crucial for maintaining optimal system performance in dynamic industrial environments. Unlike electric actuators that require time to ramp up through gear systems, pneumatic actuators deliver immediate response to control signals, enabling rapid adjustments to changing process conditions. This instantaneous response capability makes Pneumatic Ball Valve systems ideal for applications requiring quick shut-off or flow modulation in emergency situations or process control scenarios. The responsiveness of pneumatic systems stems from the compressible nature of air, which allows for rapid pressure changes that translate directly into valve movement. This characteristic enables automated systems to react quickly to sensor feedback, maintaining process parameters within specified ranges and preventing operational upsets that could compromise product quality or system safety.

Superior Energy Efficiency and Cost Reduction

-

Optimized Energy Consumption

Pneumatic systems are known for their energy efficiency, with pneumatic valves allowing for precise control of air flow, reducing energy wastage and making processes more environmentally friendly. The fundamental advantage of Pneumatic Ball Valve systems lies in their ability to utilize compressed air more efficiently than traditional mechanical systems. By providing precise control over air flow rates and pressure levels, these valves minimize energy waste while maximizing system performance, resulting in significant operational cost savings over time. The energy efficiency of pneumatic ball valves becomes particularly evident when compared to electrically operated alternatives. Pneumatic automation systems use compressed air instead of electricity, making them much more energy efficient than traditional mechanical systems, requiring less energy overall since they do not need additional power sources such as motors or pumps. This inherent efficiency translates into lower utility costs and reduced environmental impact, making pneumatic ball valves an attractive choice for sustainability-focused organizations.

-

Reduced Maintenance Costs and Downtime

The robust design and simple operation mechanism of Pneumatic Ball Valve systems contribute significantly to reduced maintenance requirements and associated costs. Unlike complex electric actuators with multiple moving parts, pneumatic actuators have fewer components that can wear out or fail, resulting in longer service intervals and reduced maintenance frequency. This reliability translates directly into lower total cost of ownership and improved system availability. The durability of pneumatic ball valves in harsh industrial environments further contributes to cost reduction by minimizing unexpected failures and emergency repairs. The ability to withstand extreme temperatures, corrosive atmospheres, and high-pressure conditions ensures consistent performance over extended periods, reducing the need for frequent valve replacements and associated downtime costs.

Enhanced Safety and Reliability in Critical Applications

-

Fail-Safe Operation Characteristics

Safety considerations are paramount in industrial automation, and Pneumatic Ball Valve systems provide inherent fail-safe capabilities that protect both equipment and personnel. In the event of power failure or control system malfunction, pneumatic valves can be configured to fail in a predetermined safe position, either fully open or fully closed, depending on process requirements. This fail-safe capability prevents dangerous conditions from developing during system upsets or emergency situations. The design of pneumatic actuators allows for the integration of spring-return mechanisms that ensure valve closure or opening upon loss of air supply, providing an additional layer of safety protection. This feature is particularly valuable in applications involving hazardous materials or high-pressure systems where rapid isolation may be necessary to prevent accidents or environmental damage.

-

Intrinsically Safe Operation

Pneumatic Ball Valve systems offer significant safety advantages in potentially explosive atmospheres where electrical equipment poses ignition risks. The absence of electrical components in the actuator mechanism eliminates the possibility of electrical sparks that could trigger explosions in hazardous environments. This makes pneumatic ball valves the preferred choice for applications in petrochemical facilities, grain handling operations, and other industries where explosive atmospheres may be present. The clean, spark-free operation of pneumatic systems ensures compliance with stringent safety regulations governing hazardous area classifications. This compliance eliminates the need for expensive explosion-proof electrical equipment and simplifies installation and maintenance procedures in potentially dangerous environments.

Versatile Application Adaptability

-

Wide Range of Operating Conditions

The versatility of Pneumatic Ball Valve technology allows these systems to operate effectively across a broad spectrum of industrial conditions and applications. From cryogenic temperatures in liquefied gas handling to high-temperature steam applications, pneumatic ball valves maintain reliable performance where other valve types might fail or require expensive modifications. This adaptability makes them suitable for diverse industries including oil and gas, chemical processing, power generation, and water treatment. The modular design of pneumatic actuators enables easy customization for specific application requirements, including different torque outputs, fail positions, and accessory configurations. This flexibility allows engineers to select optimal valve configurations for their particular process conditions without compromising performance or safety requirements.

-

Integration with Modern Control Systems

Contemporary Pneumatic Ball Valve systems seamlessly integrate with advanced process control systems through sophisticated positioning and feedback technologies. Digital positioners and smart actuators provide precise valve positioning feedback to distributed control systems, enabling advanced control strategies such as cascade control, feed-forward compensation, and predictive maintenance scheduling. The compatibility of pneumatic ball valves with industry-standard communication protocols facilitates integration with existing automation infrastructure while providing the flexibility to accommodate future system upgrades. This integration capability ensures that pneumatic valve systems can evolve with changing technology requirements without requiring complete system replacements.

Advanced Technological Integration and Smart Features

-

Digital Control and Monitoring Capabilities

Modern Pneumatic Ball Valve systems incorporate sophisticated digital technologies that enable remote monitoring, diagnostics, and control capabilities. Smart positioners equipped with microprocessors provide detailed valve performance data, including position feedback, travel times, and actuator health information. This data enables predictive maintenance strategies that can identify potential issues before they result in system failures. The integration of wireless communication technologies allows for remote valve monitoring and control from centralized control rooms, reducing the need for personnel to visit potentially hazardous field locations. This capability is particularly valuable in offshore installations, chemical plants, and other environments where personnel safety is a primary concern.

-

Intelligent Diagnostics and Predictive Maintenance

Advanced diagnostic capabilities built into modern pneumatic ball valve systems enable proactive maintenance strategies that minimize unplanned downtime and extend equipment life. Continuous monitoring of key performance parameters such as actuator pressure, valve travel time, and positioning accuracy provides early warning of developing problems, allowing maintenance personnel to schedule repairs during planned outages rather than emergency situations. The data collected by intelligent valve systems can be analyzed using machine learning algorithms to identify patterns and trends that indicate optimal maintenance timing. This predictive approach to maintenance reduces overall maintenance costs while improving system reliability and availability.

Conclusion

The implementation of Pneumatic Ball Valve technology in automated systems delivers transformative benefits that significantly enhance operational efficiency, safety, and cost-effectiveness. From superior precision control and energy efficiency to advanced diagnostic capabilities and seamless system integration, these innovative valve solutions address the critical challenges facing modern industrial operations. The combination of reliability, versatility, and advanced technological features makes pneumatic ball valves an essential component for organizations seeking to optimize their automation systems and maintain competitive advantages in today's demanding industrial landscape.

Cooperate with CEPAI Group Co., LTD.

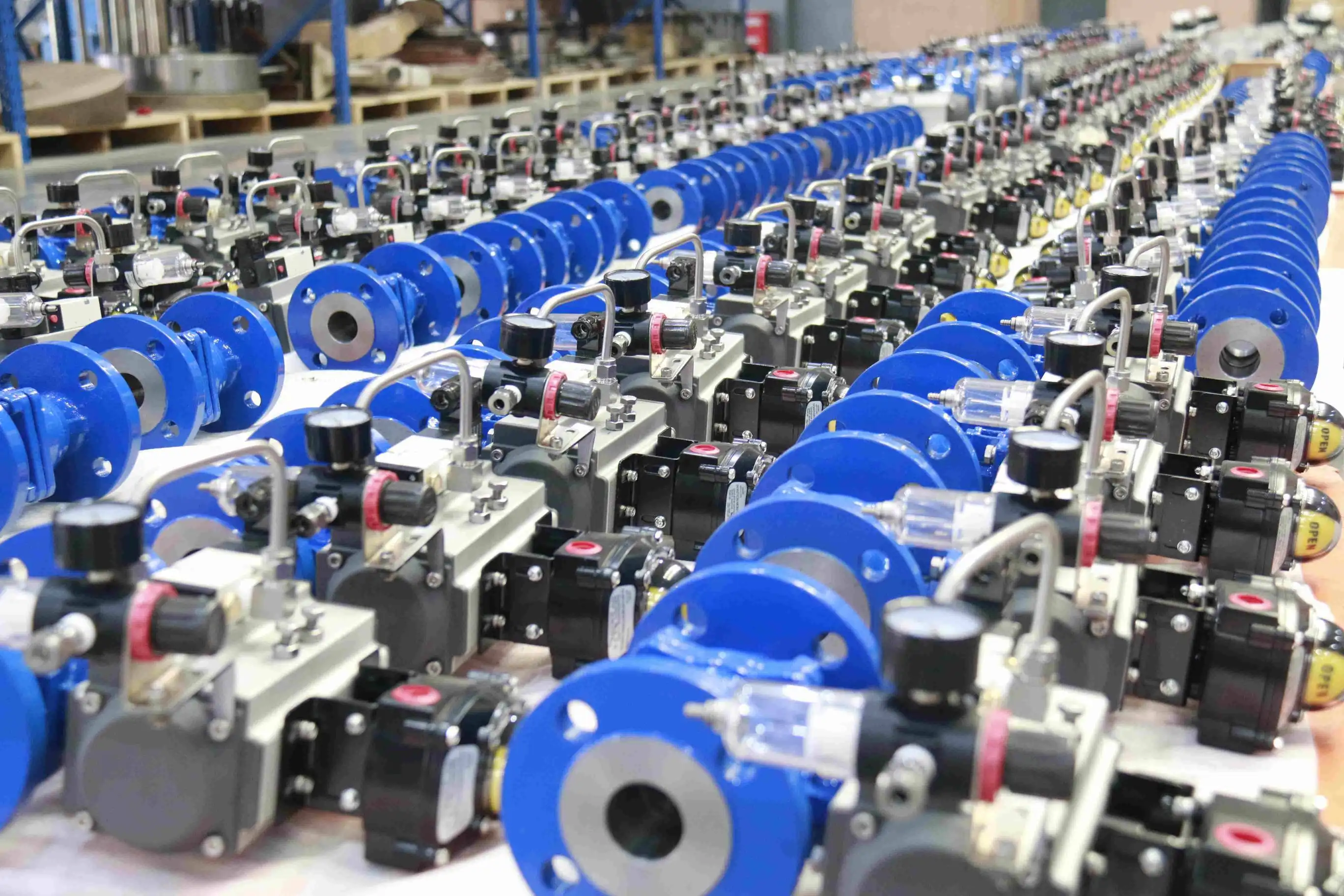

When selecting a reliable partner for high-quality Pneumatic Ball Valve solutions, CEPAI Group Co., LTD. stands as a leading China Pneumatic Ball Valve manufacturer with over 15 years of proven expertise in valve manufacturing and automation solutions. Established in January 2009 with a registered capital of 200 million yuan, CEPAI operates from a state-of-the-art 56,000 square meter facility equipped with the longest high-precision intelligent manufacturing flexible production line in the Asia Pacific region, representing a 156 million yuan investment in advanced manufacturing technology.

As a China Pneumatic Ball Valve factory certified under multiple international quality standards including ISO 9001, ISO 14001, and ISO 45001, CEPAI maintains rigorous quality control throughout the entire production process. Our comprehensive certifications including API Q1, API 6A, API 6D, CE, and SIL certifications for ball valves demonstrate our commitment to delivering High Quality Pneumatic Ball Valve products that meet the most demanding industrial requirements. The company's recognition as a national high-tech enterprise and Jiangsu Smart Factory reflects our dedication to technological innovation and intelligent manufacturing excellence.

CEPAI's extensive supplier qualifications with major industry leaders including PetroChina, Sinopec, CNOOC, China Datang Group, and Baowu Group validate our position as a trusted China Pneumatic Ball Valve supplier capable of meeting large-scale industrial demands. Our advanced testing capabilities, including CNAS nationally recognized laboratories, ensure that every Pneumatic Ball Valve for sale meets stringent quality standards from blank castings to final products through comprehensive material analysis, dimensional inspection, and final testing procedures.

Ready to enhance your automation systems with superior pneumatic ball valve technology? Contact our technical experts at cepai@cepai.com for competitive Pneumatic Ball Valve price quotes and customized solutions. As a leading China Pneumatic Ball Valve wholesale provider, we offer comprehensive pre-sales technical consultation, customized engineering solutions, installation support, and ongoing maintenance services to ensure optimal system performance and reliability.

FAQ

Q: What are the main advantages of pneumatic ball valves over electric actuated valves in automation systems?

A: Pneumatic ball valves offer faster response times, higher force output, fail-safe operation without external power, and intrinsically safe operation in hazardous environments, making them ideal for critical automation applications.

Q: How do pneumatic ball valves improve energy efficiency in automated systems?

A: Pneumatic ball valves reduce energy consumption by precisely controlling air flow rates and pressures, minimizing waste while requiring no electrical power for basic operation, resulting in significant cost savings.

Q: What industries benefit most from pneumatic ball valve automation systems?

A: Oil and gas, chemical processing, power generation, water treatment, food processing, and pharmaceutical industries benefit significantly due to requirements for precise control, safety, and reliability in their processes.

Q: What maintenance considerations are important for pneumatic ball valve systems?

A: Regular inspection of air supply quality, seal condition, and actuator performance are essential, though pneumatic systems generally require less maintenance than electric alternatives due to fewer moving parts.

References

1. "Industrial Valve Technology: Principles and Applications" by Smith, J.K. and Anderson, R.M., Industrial Press Inc.

2. "Pneumatic Control Systems: Theory and Practice" by Johnson, P.L., McGraw-Hill Professional Engineering Series.

3. "Automation and Control in Process Industries" by Williams, D.R. and Thompson, M.J., Butterworth-Heinemann Technical Publications.

4. "Valve Selection and Application Guidelines for Process Industries" by Brown, S.A., American Society of Mechanical Engineers Press.

Get professional pre-sales technical consultation and valve selection services, customized solution services.

About CEPAI