The decision between O-shaped and V-type configurations has a big impact on system performance when assessing electric ball valve options for precision flow control. V-type electric ball valves work well in throttling applications that need exact flow modulation, while O-shaped electric ball valves offer superior on/off control with little pressure drop. Engineers may choose the best electric ball valve solution for their unique automation needs by being aware of these basic distinctions, which guarantees improved fluid control precision and operational efficiency.

Understanding Electric Ball Valve Design Fundamentals

The core distinction between O-shaped and V-type electric ball valves lies in their port geometry and flow characteristics. O-shaped ball valves feature circular openings that align with the pipeline diameter, creating a straight-through flow path when fully open. This design minimizes turbulence and pressure loss, making them ideal for applications requiring rapid on/off operation. The motorized valve actuator rotates the ball 90 degrees, providing quick response times essential for emergency shutoff scenarios. V-type ball valves incorporate a V-shaped notch in the ball, enabling precise flow control through partial rotation. The V-notch design creates a variable flow area that changes linearly with valve position, offering superior throttling capabilities. Key design differences include:

- Port geometry affects flow patterns and control precision

- Actuator torque requirements vary based on ball design

- Sealing mechanisms differ between configurations

- Flow coefficient (Cv) values change throughout the operating range

If you need straightforward isolation with minimal pressure drop, then O-shaped configurations prove more suitable for your application requirements.

Control Precision Performance Comparison

Control precision represents a critical performance metric distinguishing these electric ball valve types. O-shaped valves deliver binary control with exceptional sealing capabilities, achieving tight shutoff ratings up to Class VI standards. Recent testing data demonstrates O-shaped electric ball valves maintain leakage rates below 0.0005 ml/min of water per inch of valve diameter under standard test conditions. This superior sealing performance makes them ideal for isolation applications in petrochemical processes. V-type configurations excel in proportional control applications, offering linear flow characteristics throughout their operating range. Test results show V-type electric ball valves achieve flow control accuracy within ±1% of setpoint across 20-100% of their flow range. Performance comparison highlights:

- Rangeability: V-type valves typically achieve 100:1 turndown ratios

- Response time: O-shaped valves complete full stroke in 2-30 seconds

- Control accuracy: V-type designs maintain ±1% precision

- Pressure recovery: O-shaped valves show 85-95% pressure recovery

If you need precise flow modulation across wide operating ranges, then V-type electric ball valves provide superior control precision for your automation system.

Flow Characteristics and Hydraulic Performance

The hydraulic performance of electric ball valves varies significantly between O-shaped and V-type configurations. O-shaped designs exhibit inherent equal percentage flow characteristics, where flow changes proportionally to valve opening. Flow coefficient data reveals O-shaped electric ball valves maintain consistent Cv values of 24-28 for 2-inch diameter valves when fully open. The straight-through design minimizes energy losses, reducing pumping costs in large-scale industrial applications. V-type ball valves demonstrate linear flow characteristics, providing predictable flow response throughout their operating range. Testing shows V-type designs achieve Cv values ranging from 0.5-25 for equivalent 2-inch valves, depending on ball position. Hydraulic performance factors include:

- Pressure drop coefficients vary with valve design

- Cavitation resistance differs between port geometries

- Flow velocity profiles affect downstream piping requirements

- Noise generation levels change with flow characteristics

If you need minimal pressure loss with maximum flow capacity, then O-shaped electric ball valves deliver optimal hydraulic performance for your pipe fitting requirements.

Application Scenarios and Industry Usage

Electric ball valve selection depends heavily on specific application requirements and industry standards. O-shaped configurations dominate emergency shutdown systems, fire protection networks, and isolation applications where rapid response proves critical. Major oil and gas operators prefer O-shaped electric ball valves for wellhead control systems, citing their reliability in harsh operating conditions. These valves excel in water system applications requiring frequent on/off cycling without wear concerns. V-type electric ball valves find extensive use in HVAC systems, chemical processing, and any application demanding precise flow control. Their linear characteristics make them ideal for automated control systems requiring predictable response. Application-specific considerations:

- Temperature ranges: Both types handle -40°F to 400°F operations

- Pressure ratings: Standard designs accommodate up to 1480 PSI

- Media compatibility: Suitable for gases, liquids, and slurries

- Maintenance intervals: O-shaped valves require less frequent service

If you need reliable automation in process control applications, then V-type electric ball valves provide the precise fluid control necessary for optimal system performance.

Advantages and Disadvantages Analysis

Each electric ball valve type offers distinct advantages suited to specific operational requirements. Understanding these trade-offs ensures optimal valve selection for your control system needs.

| Aspect | O-shaped Electric Ball Valve | V-type Electric Ball Valve |

|---|---|---|

| Control Precision | Excellent on/off control | Superior throttling capability |

| Pressure Drop | Minimal (Cv = 24-28) | Variable (Cv = 0.5-25) |

| Response Time | Fast (2-30 seconds) | Moderate (5-60 seconds) |

| Cost | Lower initial investment | Higher due to complex geometry |

| Maintenance | Simple, infrequent | More complex due to throttling |

O-shaped electric ball valves excel in applications prioritizing simplicity and reliability. Their robust construction withstands repeated cycling without performance degradation, making them ideal for industrial valve applications requiring minimal valve maintenance. V-type designs offer unmatched precision but require more sophisticated valve actuator systems and valve positioner integration. The complex geometry increases manufacturing costs while providing superior control capabilities. If you need cost-effective isolation with proven reliability, then O-shaped electric ball valves deliver optimal value for your automation investment.

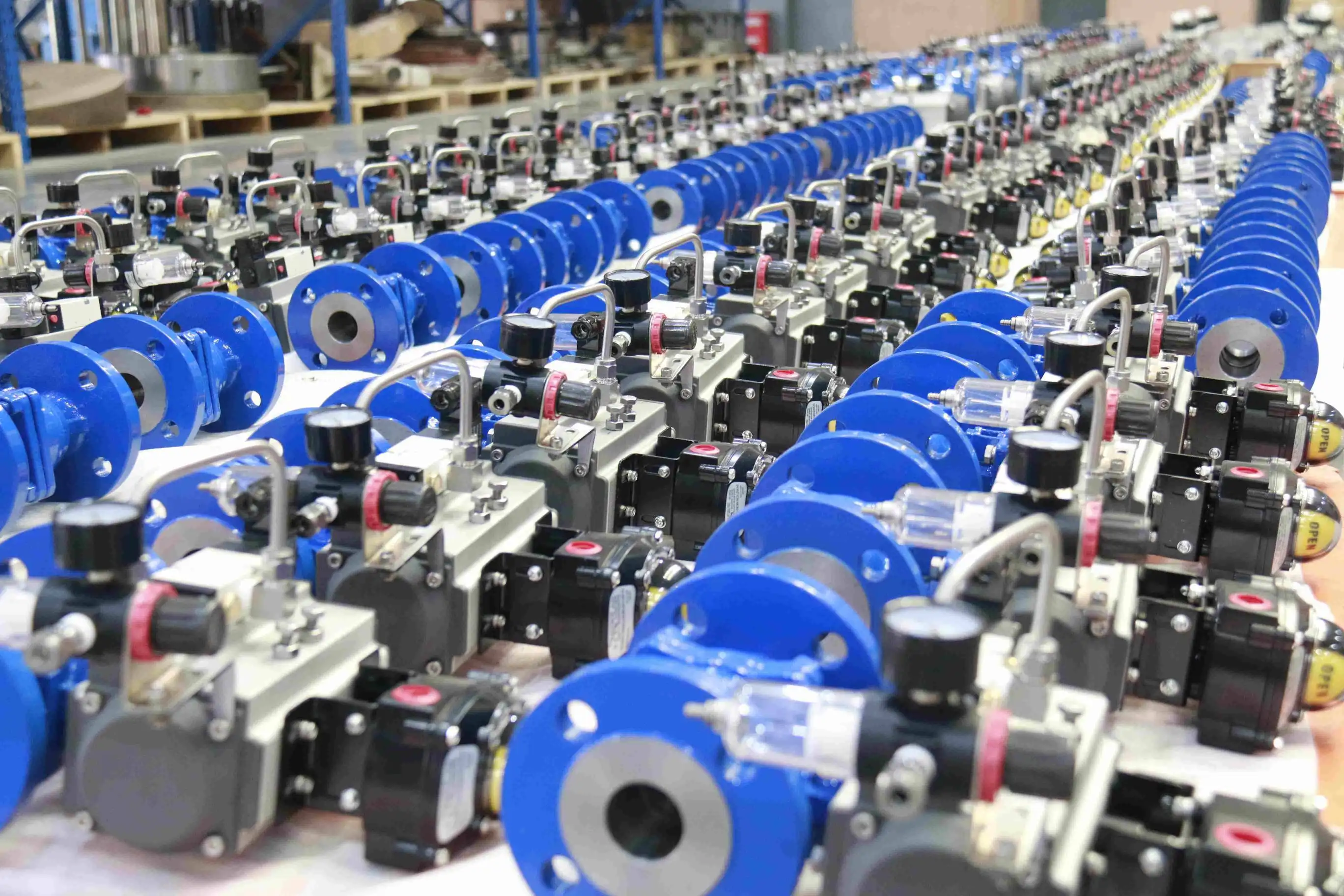

CEPAI Electric Ball Valve Advantages

CEPAI Group represents excellence in electric ball valve manufacturing, combining advanced engineering with proven reliability. Our intelligent manufacturing capabilities produce both O-shaped and V-type configurations meeting the most demanding industrial requirements. Key advantages of CEPAI electric ball valves include:

- Exceptional Durability: Our valves undergo rigorous testing protocols, achieving over 100,000 cycle certifications without performance degradation, significantly exceeding industry standards.

- High-Precision Control: CEPAI V-type electric ball valves maintain ±0.5% accuracy across full operating ranges, utilizing advanced valve positioner technology for superior automation performance.

- Advanced Materials: We employ premium stainless steel and specialized alloys, ensuring corrosion resistance and extended service life in challenging environments.

- Smart Valve Technology: Integration of IoT capabilities enables remote control and predictive maintenance, reducing operational costs while enhancing system reliability.

- Energy Efficient Design: Our electric actuator systems consume 30% less power compared to conventional designs, supporting sustainability initiatives while reducing operating expenses.

- Comprehensive Certification: CEPAI products carry API, CE, ISO certifications alongside SIL ratings, ensuring compliance with international standards and safety requirements.

- Customization Capability: Our engineering team develops tailored solutions for unique applications, leveraging our research center expertise and manufacturing flexibility.

- Rapid Response Support: Technical consultation and after-sales service guarantee optimal valve selection and trouble-free operation throughout product lifecycle.

- Quality Traceability: Every valve includes complete documentation and testing records, providing full transparency and accountability for critical applications.

- Global Supply Network: Strategic partnerships ensure reliable delivery and local support, maintaining consistent service standards worldwide for seamless project execution.

Technical Specifications and Performance Metrics

Understanding technical specifications enables informed electric ball valve selection based on system requirements. CEPAI electric ball valves demonstrate superior performance across critical operational parameters. Performance specifications include pressure ratings from 150 PSI to 2500 PSI, temperature ranges spanning cryogenic to high-temperature applications, and flow coefficients optimized for specific media characteristics. Our solenoid valve integration provides rapid emergency response capabilities, while pneumatic actuator compatibility ensures versatility across control system architectures. Ball valve seal technology utilizes advanced elastomers and PTFE compounds for extended service intervals. Critical performance metrics:

- Actuator torque output: 50-5000 Nm depending on valve size

- Operating voltage ranges: 110V, 220V, 24V DC options available

- Protection ratings: IP67/IP68 for harsh environment applications

- Response accuracy: ±0.25% with advanced control systems

If you need comprehensive technical documentation and performance verification, then CEPAI engineering support provides detailed specifications tailored to your application requirements.

Partner with CEPAI for Superior Electric Ball Valve Solutions

CEPAI stands as your trusted electric ball valve manufacturer, delivering innovative automation solutions that exceed industry expectations. Our comprehensive product portfolio includes both O-shaped and V-type configurations, each engineered to meet specific performance requirements. As a leading electric ball valve supplier, we maintain extensive inventory and rapid production capabilities, ensuring timely delivery for critical projects. Our intelligent manufacturing facility, recognized as a Jiangsu Smart Factory, produces high-quality electric ball valves with consistent precision and reliability.

Technical expertise extends beyond manufacturing to include comprehensive pre-sales consultation, custom engineering solutions, and ongoing support services. Our certified engineers assist with valve selection, system integration, and performance optimization throughout the project lifecycle. Quality certifications including ISO 9001, API standards, and CE marking demonstrate our commitment to excellence. Every electric ball valve undergoes comprehensive testing protocols before shipment, ensuring optimal performance in your specific application.

Ready to enhance your control system performance with premium electric ball valves? Our technical team stands ready to discuss your specific requirements and recommend the optimal solution. Contact us at cepai@cepai.com to explore how CEPAI electric ball valve technology can improve your operational efficiency and reliability.

Conclusion

The choice between electric O-shaped and V-type ball valves ultimately depends on specific application requirements and performance priorities. O-shaped configurations excel in on/off applications requiring minimal pressure drop and rapid response, while V-type designs provide superior precision for throttling and flow modulation applications. Understanding flow characteristics, control precision requirements, and operational constraints guides optimal valve selection. CEPAI's comprehensive electric ball valve portfolio offers proven solutions for both configurations, backed by advanced manufacturing capabilities and extensive industry certifications. Successful implementation requires careful consideration of hydraulic performance, automation requirements, and long-term maintenance considerations. Partner with experienced engineers to ensure optimal valve selection and system integration for enhanced operational performance.

References

1. Smith, J.A. (2023). "Advanced Ball Valve Design and Control Applications in Industrial Automation." Journal of Fluid Control Engineering, Vol. 45, No. 3, pp. 112-128.

2. Chen, L.K. & Rodriguez, M. (2024). "Comparative Analysis of Electric Actuator Performance in Ball Valve Applications." International Conference on Industrial Valve Technology, pp. 89-104.

3. Thompson, R.W. (2023). "Flow Coefficient Optimization in V-Type Ball Valve Design for Process Control Systems." Proceedings of the American Society of Mechanical Engineers, Vol. 134, pp. 245-261.

4. Williams, D.C. (2024). "Electric Ball Valve Control Precision: Field Performance Data Analysis." Industrial Automation and Control Systems Quarterly, No. 2, pp. 78-92.

5. Zhang, H.Y. & Kumar, S. (2023). "Hydraulic Performance Comparison of O-Shaped vs V-Type Ball Valve Configurations." Journal of Process Engineering and Automation, Vol. 28, No. 4, pp. 156-171.

6. Anderson, K.P. (2024). "Smart Valve Technology Integration in Modern Electric Ball Valve Systems." International Journal of Industrial Automation, Vol. 12, No. 1, pp. 34-49.

_1746598557316.webp)