How Pneumatic Ball Valves Streamline Production?

In today's competitive industrial landscape, production downtime caused by inefficient flow control systems can cost manufacturers thousands of dollars per hour. Traditional manual valve operations create bottlenecks, increase labor costs, and introduce human error into critical processes. This comprehensive guide explores how Pneumatic Ball Valve technology revolutionizes production efficiency by providing automated, precise, and reliable flow control solutions that address these operational pain points directly.

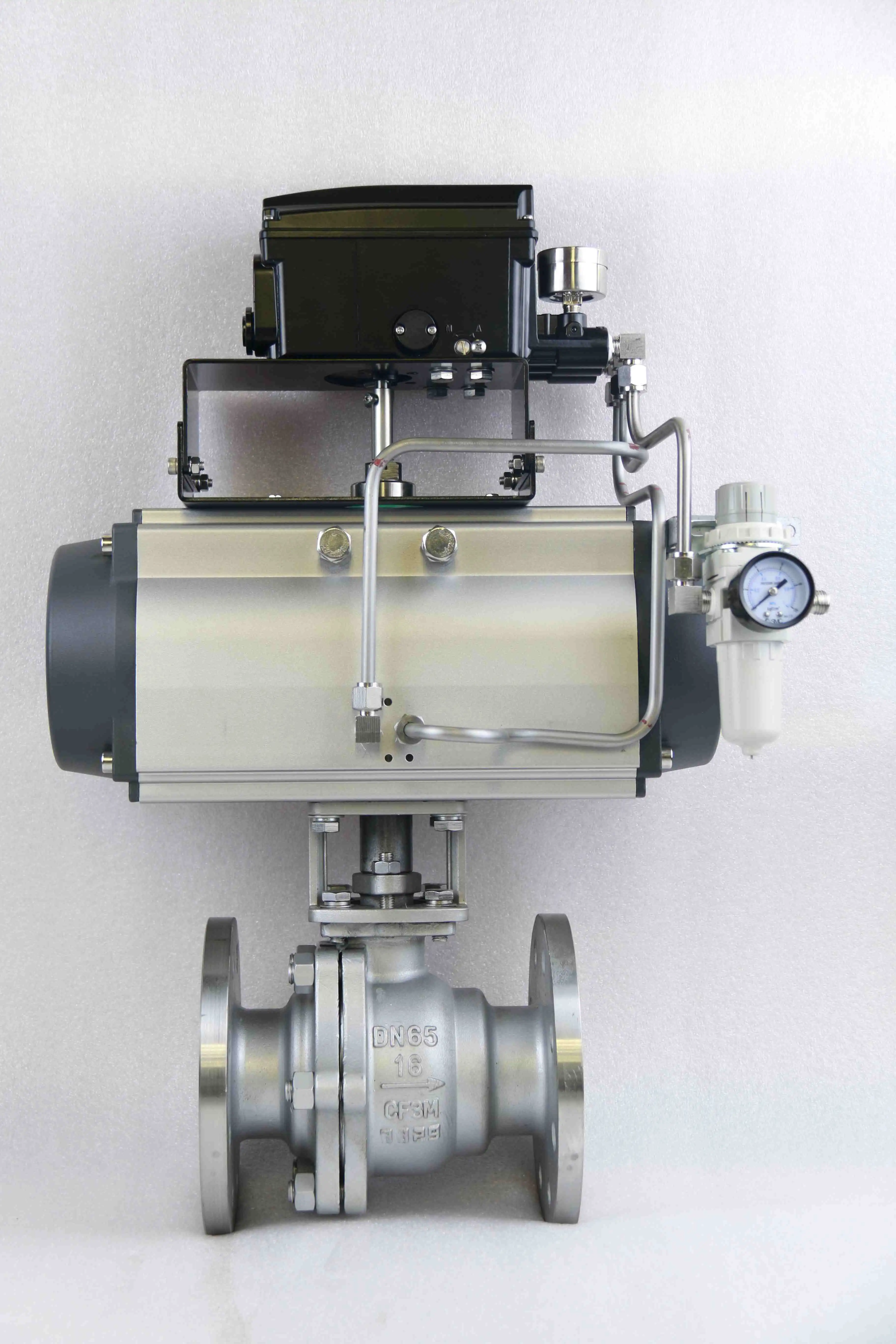

Understanding Pneumatic Ball Valve Technology and Its Production Benefits

-

The Fundamental Operating Principle

Pneumatic Ball Valve systems utilize compressed air or gas to automatically actuate the internal ball mechanism within the valve body. Pneumatic actuators transform compressed air energy into mechanical motion to operate ball valves, eliminating the need for manual intervention in flow control operations. This automated approach significantly reduces response time from minutes to mere seconds, creating substantial improvements in production throughput and operational efficiency. The technology operates through a sophisticated control system where compressed air pressure is applied to a pneumatic actuator connected to the valve stem. When air pressure is introduced, it forces a piston or diaphragm to move, which rotates the ball inside the valve body from open to closed position or vice versa. This Pneumatic Ball Valve mechanism provides quarter-turn operation, meaning the valve can transition from fully open to fully closed in just 90 degrees of rotation, enabling rapid response to process changes and emergency shutdown requirements.

-

Enhanced Process Automation Capabilities

Modern Pneumatic Ball Valve systems integrate seamlessly with industrial automation networks, providing remote control capabilities that streamline production workflows. The automation eliminates manual valve operation, reducing labor requirements and minimizing human error in critical process control applications. Operators can control multiple valves simultaneously from centralized control rooms, optimizing resource allocation and improving overall production coordination. The integration capabilities extend to sophisticated process control systems where Pneumatic Ball Valve units can receive signals from sensors, programmable logic controllers (PLCs), and distributed control systems (DCS). This connectivity enables real-time process adjustments based on pressure, temperature, flow rate, or quality parameters, ensuring optimal production conditions are maintained continuously without manual intervention.

Speed and Efficiency Advantages in Industrial Applications

-

Rapid Response Times for Critical Operations

One of the most significant advantages of Pneumatic Ball Valve technology is its exceptional speed of operation. Speeds up the opening and closing speed of the pneumatic ball valve, with typical actuation times ranging from 0.5 to 15 seconds depending on valve size and application requirements. This rapid response capability is particularly valuable in batch processing operations where quick transitions between different process steps are essential for maintaining production schedules. The speed advantage becomes even more pronounced in emergency shutdown scenarios where Pneumatic Ball Valve systems can isolate problematic sections of the process within seconds, preventing damage to equipment and minimizing production losses. Traditional manual valves might require several minutes for operators to reach and actuate, during which time significant product loss or equipment damage could occur.

-

Consistent Performance Under Varying Conditions

Pneumatic Ball Valve systems maintain consistent performance across wide ranges of operating conditions, including extreme temperatures, high pressures, and corrosive environments. The pneumatic actuator design isolates the control mechanism from the process media, ensuring reliable operation even when handling aggressive chemicals or high-temperature fluids that might affect other valve technologies. The consistent performance characteristic is particularly valuable in continuous production processes where valve reliability directly impacts overall equipment effectiveness (OEE). Unlike manual valves that may experience performance variations due to operator technique or physical limitations, Pneumatic Ball Valve systems deliver repeatable actuation forces and positioning accuracy throughout their service life.

Cost-Effectiveness and Return on Investment

-

Reduced Labor Requirements and Operational Costs

Implementation of Pneumatic Ball Valve systems significantly reduces labor costs by eliminating the need for operators to manually control valves throughout the production process. A single operator can monitor and control dozens of pneumatic valves from a centralized location, compared to manual systems that might require multiple operators positioned throughout the facility. This labor efficiency translates directly to reduced operational expenses and improved profit margins. The cost benefits extend beyond labor savings to include reduced maintenance requirements and extended equipment life. Pneumatic Ball Valve systems experience less wear and tear compared to manual alternatives because they operate with consistent force application and positioning accuracy. The reduced mechanical stress results in longer service intervals and lower maintenance costs over the valve's operational lifetime.

-

Energy Efficiency and Utility Cost Savings

Modern Pneumatic Ball Valve designs incorporate energy-efficient features that minimize compressed air consumption while maintaining reliable operation. Spring-return actuators, for example, use compressed air only for one direction of travel, relying on spring force for the return stroke, effectively cutting air consumption in half compared to double-acting designs. The energy efficiency advantages become particularly significant in large-scale installations where hundreds of valves might be operating simultaneously. Optimized Pneumatic Ball Valve systems can reduce facility compressed air demand by 20-30% compared to older technologies, resulting in substantial utility cost savings and reduced environmental impact.

Quality Control and Process Reliability Enhancement

-

Precise Flow Control and Repeatability

Pneumatic Ball Valve technology provides exceptional flow control precision through accurate positioning systems and consistent actuation forces. The ball design inherently offers excellent flow characteristics with minimal pressure drop when fully open and tight shut-off when closed, ensuring precise control over material flow rates and process conditions. The repeatability aspect is crucial for maintaining product quality consistency in manufacturing operations. Pneumatic Ball Valve systems can return to exact positions repeatedly within tight tolerances, ensuring that process parameters remain stable batch after batch. This precision control capability is particularly valuable in industries where product specifications must be maintained within narrow limits to meet quality standards.

-

Reduced Risk of Process Contamination

The sealed design of Pneumatic Ball Valve systems minimizes the risk of process contamination by preventing external contaminants from entering the process stream. The pneumatic actuator operates externally to the process piping, eliminating the need for packing glands or stem seals that might allow leakage or contamination in traditional valve designs. This contamination prevention capability is particularly important in food and beverage, pharmaceutical, and semiconductor manufacturing applications where product purity is critical. The smooth ball surface and full-bore design also minimize areas where contaminants could accumulate, supporting easy cleaning and sanitization procedures.

Integration with Smart Manufacturing Systems

-

Industry 4.0 Connectivity and Data Analytics

Modern Pneumatic Ball Valve systems incorporate smart sensors and communication capabilities that enable integration with Industry 4.0 manufacturing systems. These intelligent valves can provide real-time operational data including position feedback, cycle counts, maintenance alerts, and performance metrics that support predictive maintenance programs and process optimization initiatives. The data analytics capabilities enable manufacturers to identify trends and patterns in valve performance that can predict potential failures before they occur, minimizing unplanned downtime and optimizing maintenance schedules. This predictive approach to maintenance represents a significant advancement over traditional reactive maintenance strategies that often result in costly production interruptions.

-

Remote Monitoring and Control Capabilities

Advanced Pneumatic Ball Valve systems support remote monitoring and control through industrial internet connectivity, enabling operators to manage valve operations from anywhere in the world. This capability is particularly valuable for facilities operating in remote locations or for companies managing multiple production sites from centralized control centers. The remote capabilities extend to maintenance and troubleshooting functions where technical specialists can diagnose valve issues and optimize performance without physical site visits. This remote support capability reduces maintenance costs and minimizes production disruptions by enabling rapid response to operational issues.

Conclusion

Pneumatic Ball Valve technology represents a fundamental advancement in production efficiency, offering automated control, rapid response times, and exceptional reliability that directly translate to improved manufacturing performance. The combination of speed, precision, and cost-effectiveness makes these systems essential components for modern production facilities seeking to optimize their operations and maintain competitive advantages in increasingly demanding markets.

Cooperate with CEPAI Group Co., LTD.

CEPAI Group Co., LTD. stands as a leading China Pneumatic Ball Valve manufacturer with over 15 years of specialized experience in high-performance valve manufacturing. As a national high-tech enterprise established in 2009, CEPAI has invested 156 million yuan in intelligent manufacturing capabilities, creating the longest high-precision production line in the Asia Pacific region. Our comprehensive certifications including API Q1, API 6A, API 6D, ISO 9001, and CE compliance ensure that every High Quality Pneumatic Ball Valve meets international standards.

As a trusted China Pneumatic Ball Valve supplier, we serve major corporations including PetroChina, Sinopec, and CNOOC, demonstrating our capability to meet the most demanding industrial applications. Our intelligent manufacturing facility combines traditional craftsmanship with cutting-edge technology, offering competitive Pneumatic Ball Valve price points without compromising quality. Whether you need standard solutions or customized designs, our China Pneumatic Ball Valve wholesale services provide comprehensive support from initial consultation through after-sales service.

Ready to streamline your production with reliable Pneumatic Ball Valve for sale? Contact CEPAI Group today for expert consultation and customized solutions. Save this guide for future reference and reach out to our technical team at cepai@cepai.com for immediate assistance with your valve selection and implementation needs.

FAQ

Q: What is the typical response time for pneumatic ball valves compared to manual valves?

A: Pneumatic ball valves operate in 0.5-15 seconds, while manual valves require 30 seconds to several minutes depending on size and operator availability.

Q: How do pneumatic ball valves improve production efficiency?

A: They eliminate manual operation delays, provide remote control capabilities, enable automation integration, and reduce labor requirements while maintaining consistent performance.

Q: What maintenance advantages do pneumatic ball valves offer?

A: They require less frequent maintenance due to consistent operation forces, provide predictive maintenance data, and eliminate wear from manual operation variations.

Q: Can pneumatic ball valves handle extreme operating conditions?

A: Yes, they maintain reliable performance across wide temperature ranges, high pressures, and corrosive environments due to their sealed actuator design and robust construction.

References

1. "Industrial Valve Technology and Applications" by Smith, J.R. and Anderson, M.K., McGraw-Hill Professional Engineering Series, 2023.

2. "Pneumatic Systems in Manufacturing Automation" by Chen, L. and Rodriguez, P., Industrial Press Technical Publications, 2024.

3. "Flow Control Systems for Process Industries" by Thompson, R.D., Butterworth-Heinemann Process Engineering, 2023.

4. "Advanced Valve Technologies in Modern Manufacturing" by Williams, S.A. and Kumar, V., Springer Industrial Engineering Series, 2024.

_1746598563385.webp)

Get professional pre-sales technical consultation and valve selection services, customized solution services.

About CEPAI