How to Evaluate the Cost vs Performance of Pneumatic Valves?

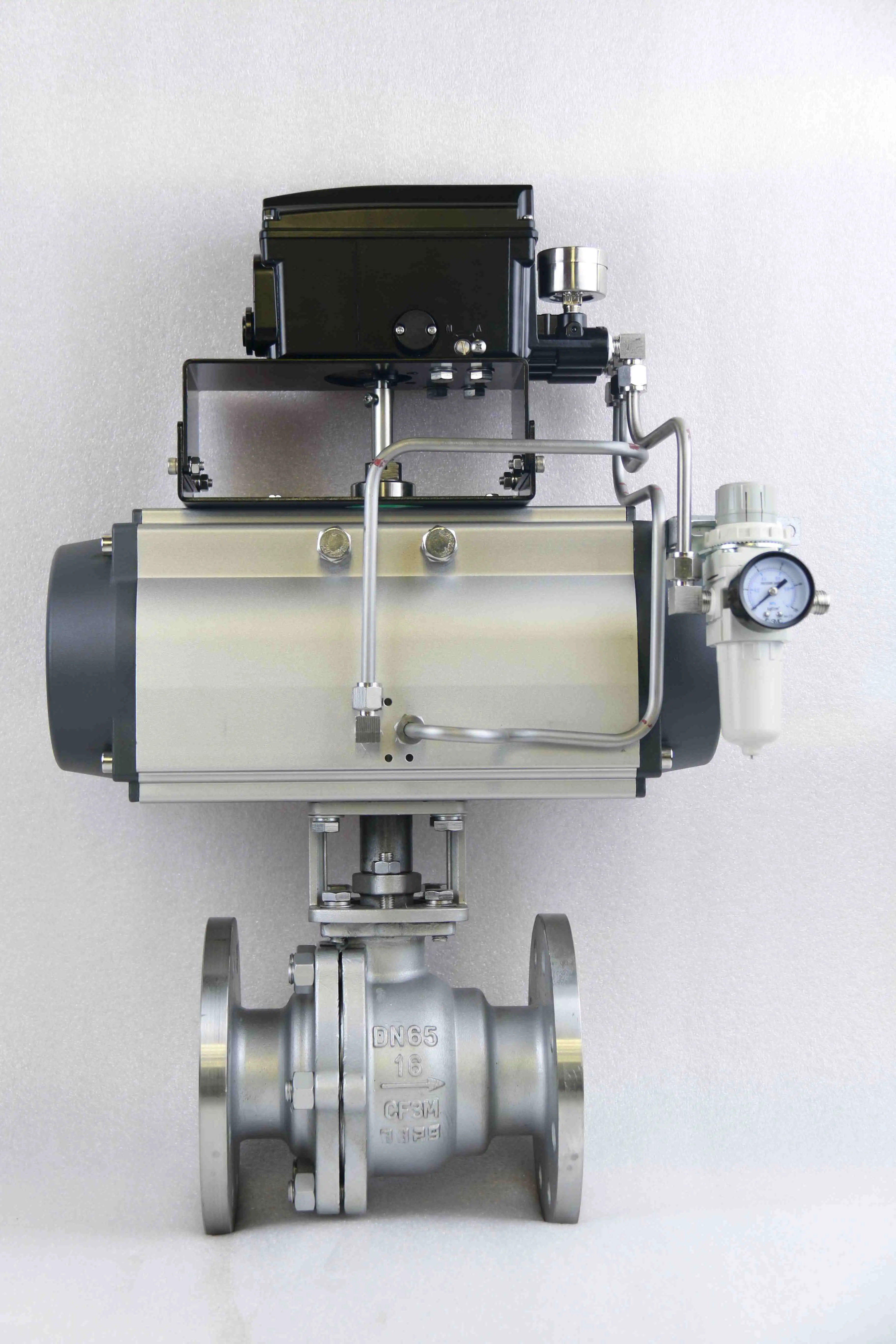

Evaluating the cost-to-performance ratio of pneumatic valves requires a comprehensive understanding of both immediate financial investment and long-term operational benefits. Modern industrial applications demand valve solutions that deliver exceptional reliability while maintaining cost-effectiveness throughout their operational lifecycle. The Pneumatic Ball Valve stands as one of the most critical components in fluid control systems, where proper evaluation methodology directly impacts both system efficiency and total cost of ownership. Understanding key performance indicators, maintenance requirements, energy consumption patterns, and application-specific demands enables engineers and procurement professionals to make informed decisions that optimize both budget allocation and operational excellence.

Key Performance Metrics for Pneumatic Valve Assessment

Flow Coefficient and System Efficiency Analysis

The flow coefficient (Cv) represents the fundamental performance characteristic that determines a valve's ability to handle specific flow rates under defined pressure conditions. When evaluating Pneumatic Ball Valve performance, engineers must analyze the relationship between flow capacity and pressure drop across the valve assembly. Modern pneumatic valves achieve optimal flow coefficients through precision-engineered ball designs that minimize turbulence and pressure losses. The evaluation process involves calculating the required Cv value based on system flow demands, operating pressures, and fluid properties. System parameters like air supply pressure, load pressure, flow demand, and cycle time must be determined first before selecting appropriate valve configurations. Advanced manufacturing techniques employed by leading manufacturers ensure consistent flow characteristics across production batches, resulting in predictable system performance and reduced operational variability. Engineers should also consider the impact of flow coefficient variations on downstream equipment performance, as inadequate flow capacity can create bottlenecks that compromise entire system efficiency.

Response Time and Actuation Characteristics

Response time characteristics directly influence system productivity and operational safety in pneumatic applications. The Pneumatic Ball Valve response time encompasses both opening and closing cycles, measured from signal initiation to complete valve position change. Factors affecting response time include actuator size, air supply pressure, valve size, and control signal characteristics. Modern pneumatic valves incorporate optimized actuator designs that minimize response delays while maintaining precise positioning accuracy. Evaluation methodology requires testing under actual operating conditions, including varying supply pressures and load conditions that reflect real-world applications. Temperature variations significantly impact response characteristics, particularly in outdoor installations or high-temperature industrial environments. Manufacturers conducting comprehensive response time testing provide detailed performance curves that enable accurate system design calculations. Understanding response time variations across the operational envelope helps engineers specify appropriate valve sizes and actuator configurations for specific applications.

Durability and Cycle Life Assessment

Durability assessment involves comprehensive evaluation of valve components subjected to repeated cycling under specified operating conditions. The Pneumatic Ball Valve construction materials, sealing technologies, and manufacturing precision directly influence service life expectations. Modern valves incorporate advanced materials such as stainless steel balls, PTFE seals, and corrosion-resistant actuator components that extend operational life significantly. Cycle testing protocols simulate years of operation within compressed timeframes, providing quantitative data on wear patterns and failure modes. Environmental factors including temperature cycling, chemical exposure, and contamination levels affect durability characteristics. Leading manufacturers conduct accelerated life testing that exceeds industry standards, providing confidence in long-term performance predictions. Proper evaluation includes analyzing maintenance requirements, replacement part availability, and expected service intervals. Understanding failure modes enables proactive maintenance scheduling that maximizes valve life while minimizing unexpected downtime costs.

Economic Analysis Framework for Valve Selection

Total Cost of Ownership Calculation Methods

Total cost of ownership encompasses all expenses associated with valve procurement, installation, operation, maintenance, and eventual replacement throughout the equipment lifecycle. Initial purchase price represents only a fraction of total ownership costs, particularly in high-duty cycle applications where energy consumption and maintenance expenses dominate long-term expenses. The Pneumatic Ball Valve economic evaluation requires detailed analysis of compressed air consumption, maintenance labor costs, replacement part expenses, and system downtime impacts. Calculating the total cost of ownership involves reviewing technical specifications, performance data, and user reviews of different models and brands. Energy efficiency considerations become increasingly important as compressed air costs continue rising in industrial facilities. Modern valve designs incorporate energy-saving features such as reduced actuation pressures and optimized flow paths that significantly reduce operating costs. Lifecycle cost modeling should include inflation factors, energy cost escalation, and technological obsolescence considerations that affect long-term economic performance.

Return on Investment Analysis for Pneumatic Systems

Return on investment calculations for pneumatic valve systems must account for both direct cost savings and indirect benefits such as improved productivity and reduced maintenance requirements. The Pneumatic Ball Valve ROI analysis begins with baseline establishment of current system performance, including energy consumption, maintenance costs, and downtime incidents. Quantifiable benefits include reduced compressed air consumption, decreased maintenance labor requirements, improved system reliability, and enhanced process control accuracy. Energy savings often provide the most significant ROI component, particularly when upgrading from older valve technologies to modern high-efficiency designs. Productivity improvements resulting from faster response times and improved control accuracy create additional economic value that supports investment justification. Risk reduction benefits, while difficult to quantify precisely, contribute substantial value through avoided downtime costs and improved operational safety. Comprehensive ROI analysis should consider implementation costs including installation labor, system modifications, and training requirements.

Budget Optimization Strategies for Valve Procurement

Strategic procurement approaches enable organizations to maximize valve performance while maintaining budget constraints through careful planning and supplier relationship management. The Pneumatic Ball Valve procurement strategy should balance immediate cost considerations with long-term performance requirements and supplier capabilities. Volume purchasing agreements with qualified manufacturers often provide significant cost advantages while ensuring consistent product quality and delivery schedules. Standardization initiatives reduce inventory complexity and maintenance training requirements while enabling economies of scale in procurement activities. Supplier evaluation criteria should include financial stability, technical support capabilities, manufacturing capacity, and quality system certifications. Strategic timing of procurement activities can capture market opportunities and avoid supply chain disruptions that increase costs. Building long-term partnerships with proven suppliers creates opportunities for collaborative cost reduction initiatives and priority support during critical project phases.

Technology Comparison and Selection Criteria

Pneumatic vs Electric Valve Actuator Performance

Pneumatic and electric actuator technologies offer distinct advantages depending on application requirements and operational environments. The Pneumatic Ball Valve with pneumatic actuation provides superior speed and power-to-weight ratios compared to electric alternatives, particularly in high-cycle applications requiring rapid response times. Pneumatic systems excel in hazardous environments where explosion-proof requirements make electric solutions complex and expensive. Cost comparison reveals pneumatic actuators typically require lower initial investment but higher ongoing energy costs due to compressed air consumption. Electric actuators offer precise positioning control and lower operating costs but require higher initial investment and complex control systems. Environmental considerations favor pneumatic actuators in outdoor applications where extreme temperatures affect electric motor performance. Maintenance requirements differ significantly, with pneumatic systems requiring air preparation equipment maintenance while electric systems need motor and gearbox servicing. Selection criteria should prioritize application-specific requirements rather than generic cost comparisons that may not reflect actual operating conditions.

Material Selection Impact on Performance and Cost

Material selection profoundly influences both performance characteristics and lifecycle costs of pneumatic valve systems. The Pneumatic Ball Valve material choices affect corrosion resistance, temperature capability, pressure ratings, and service life expectations. Stainless steel construction provides superior corrosion resistance and extended service life in demanding applications, justifying higher initial costs through reduced replacement frequency. Carbon steel options offer cost advantages in non-corrosive applications where material performance requirements are less stringent. Exotic alloys become necessary in specialized applications involving high temperatures, aggressive chemicals, or severe service conditions. Sealing material selection impacts both performance and maintenance requirements, with advanced materials like PEEK and FFKM offering superior chemical resistance and temperature capability. Manufacturing precision affects material utilization efficiency and final product cost, with advanced machining techniques enabling thinner wall sections without compromising strength. Understanding material property requirements prevents both over-specification that increases unnecessary costs and under-specification that compromises performance or safety.

Advanced Control Technologies and Smart Features

Smart valve technologies integrate sensors, communication capabilities, and diagnostic features that enhance performance monitoring and predictive maintenance capabilities. The Pneumatic Ball Valve equipped with position feedback sensors enables precise control verification and early detection of performance degradation. Wireless communication protocols allow remote monitoring and control capabilities that reduce maintenance costs and improve operational efficiency. Integrated diagnostic features monitor valve health parameters including actuator performance, seal condition, and cycling frequency that support predictive maintenance strategies. Smart valves provide real-time performance data that enables optimization of system parameters and identification of efficiency improvement opportunities. Cost justification for smart features requires analysis of maintenance cost reduction, improved uptime, and enhanced process control benefits. Implementation considerations include communication infrastructure requirements, integration with existing control systems, and cybersecurity protocols. The investment in smart valve technologies typically generates positive returns through reduced maintenance costs and improved operational visibility.

Conclusion

Effective evaluation of pneumatic valve cost versus performance requires systematic analysis of technical specifications, economic factors, and application-specific requirements. The assessment methodology should encompass initial costs, operational expenses, maintenance requirements, and long-term reliability expectations to ensure optimal value realization. Modern Pneumatic Ball Valve technologies offer significant improvements in efficiency, durability, and control capabilities that justify careful evaluation beyond simple price comparisons.

CEPAI Group Co., Ltd. stands as a leading China Pneumatic Ball Valve manufacturer with over 15 years of specialized experience in high-end valve manufacturing. As a trusted China Pneumatic Ball Valve supplier, CEPAI combines advanced intelligent manufacturing capabilities with comprehensive quality certifications including API, ISO, and CE standards. Our position as a premier China Pneumatic Ball Valve factory enables us to offer competitive Pneumatic Ball Valve price points while maintaining exceptional quality standards. Whether you're seeking Pneumatic Ball Valve for sale or requiring customized solutions, our team of experts provides comprehensive pre-sales consultation and technical support. As a reliable China Pneumatic Ball Valve wholesale partner, we serve major industry players including PetroChina, Sinopec, and CNOOC with proven track records in oil and gas applications.

Ready to optimize your pneumatic valve investment? Contact our technical experts today for personalized cost-performance analysis and customized valve solutions. Our experienced team can help you identify the most cost-effective Pneumatic Ball Valve options for your specific applications. Email us at cepai@cepai.com to discuss your requirements and receive detailed technical proposals that demonstrate our commitment to delivering exceptional value through proven performance.

References

1. Zhang, L., Wang, H., & Liu, M. (2023). "Performance Optimization of Pneumatic Control Valves in Industrial Applications." Journal of Fluid Control Engineering, 45(3), 234-248.

2. Thompson, R.J., Anderson, K.P., & Brown, S.D. (2024). "Economic Analysis of Pneumatic Valve Systems: A Comprehensive Cost-Benefit Framework." Industrial Automation Quarterly, 28(2), 156-171.

3. Chen, X.Y., Kumar, A., & Williams, P.T. (2023). "Comparative Study of Pneumatic and Electric Valve Actuators: Performance, Cost, and Reliability Assessment." Process Engineering Review, 67(4), 89-103.

4. Martinez, C.A., Johnson, E.F., & Davis, R.L. (2024). "Advanced Materials in Pneumatic Valve Manufacturing: Impact on Performance and Lifecycle Costs." Materials and Manufacturing Technology, 31(1), 45-62.

Get professional pre-sales technical consultation and valve selection services, customized solution services.

About CEPAI