Best Automated Electric Ball Valves for Smooth Operations

In today's rapidly evolving industrial landscape, the demand for precision, reliability, and efficiency has never been higher. When it comes to fluid control systems across petrochemical, power generation, and manufacturing sectors, the Electric Ball Valve stands as a cornerstone technology that determines operational success. These sophisticated devices combine the fundamental principle of quarter-turn ball valve operation with advanced electric actuation systems, delivering unparalleled control precision and automation capabilities. The best automated electric ball valves not only ensure smooth operations but also provide enhanced safety features, reduced maintenance requirements, and seamless integration with modern industrial control systems, making them indispensable for facilities seeking to optimize their fluid handling processes.

Key Features That Define Superior Electric Ball Valve Performance

Advanced Actuation Technology for Precision Control

Modern Electric Ball Valve systems incorporate cutting-edge actuator technology that transforms traditional manual valve operations into sophisticated automated processes. These actuators utilize high-torque electric motors combined with precision gear reduction systems, enabling accurate positioning and consistent performance across varying pressure and temperature conditions. The integration of smart positioning technology allows for precise control within 0.1% accuracy, ensuring that fluid flow rates can be maintained exactly as specified by process requirements. Advanced Electric Ball Valve designs feature multi-turn capabilities with programmable positioning stops, allowing operators to set specific opening percentages that correspond to optimal flow characteristics for different operational scenarios. The actuator systems are designed with fail-safe mechanisms that automatically position the valve to a predetermined safe state during power failures, enhancing overall system safety and preventing potential damage to downstream equipment.

Robust Construction Materials and Design Excellence

The construction quality of an Electric Ball Valve directly impacts its longevity and reliability in demanding industrial environments. Premium electric ball valves feature bodies manufactured from high-grade stainless steel, carbon steel, or specialized alloys designed to withstand extreme temperatures, corrosive media, and high-pressure applications. The ball and seat components utilize advanced materials such as PTFE, PEEK, or metal-seated configurations depending on the specific application requirements. These Electric Ball Valve designs incorporate floating or trunnion-mounted ball configurations, with trunnion-mounted designs providing superior support for larger valve sizes and higher pressure ratings. The stem sealing systems employ multiple barrier protection including O-rings, packing glands, and bellows seals to ensure zero leakage performance throughout the valve's operational life. Additionally, fire-safe designs meeting API 607 standards provide critical safety features for hydrocarbon service applications, ensuring valve integrity even under extreme fire conditions.

Smart Integration and Monitoring Capabilities

Contemporary Electric Ball Valve systems excel through their integration with industrial automation networks and monitoring systems. These valves feature built-in position feedback sensors, torque monitoring capabilities, and diagnostic systems that provide real-time operational data to central control systems. The integration of fieldbus communication protocols such as Profibus, DeviceNet, or Ethernet/IP enables seamless connectivity with SCADA systems and distributed control systems. Advanced Electric Ball Valve controllers incorporate predictive maintenance algorithms that monitor operational parameters including actuator current draw, cycle counts, and environmental conditions to predict maintenance requirements before failures occur. Remote monitoring capabilities allow operators to adjust valve positions, monitor performance metrics, and receive diagnostic alerts from centralized control rooms, significantly reducing the need for manual field inspections and improving overall operational efficiency.

Applications and Industry-Specific Benefits

Petrochemical and Oil & Gas Operations

The petrochemical industry presents some of the most challenging operating conditions for fluid control equipment, making the selection of appropriate Electric Ball Valve systems critical for operational success. In upstream oil and gas operations, these valves manage wellhead control, pipeline isolation, and production flow regulation under extreme pressure and temperature conditions. The ability of Electric Ball Valve systems to provide rapid shut-off capabilities is essential for emergency shutdown systems, where quick response times can prevent catastrophic incidents. Refinery applications benefit from the precise flow control capabilities of electric ball valves in distillation processes, where maintaining exact flow rates directly impacts product quality and yield. The Electric Ball Valve's ability to handle various hydrocarbon media, from light gases to heavy crude oils, while maintaining tight shut-off performance, makes them invaluable for tank farm operations, pipeline transfers, and process unit isolation. Additionally, the automation capabilities reduce operator exposure to hazardous environments while improving process consistency and safety compliance.

Power Generation and Utility Applications

Power generation facilities rely heavily on Electric Ball Valve technology for both conventional and renewable energy systems. In thermal power plants, these valves control steam flows, cooling water systems, and fuel gas supplies with the precision required for optimal efficiency and emissions control. The rapid response characteristics of Electric Ball Valve systems are particularly valuable in load-following operations where power output must be adjusted quickly to match grid demand. Nuclear facilities utilize specialized electric ball valves designed to meet stringent nuclear quality standards, providing reliable isolation and control functions in both primary and secondary cooling systems. Renewable energy applications, including geothermal and biomass facilities, benefit from the adaptability of Electric Ball Valve systems to handle varying fluid characteristics and operating conditions. The integration capabilities allow these valves to respond automatically to grid signals and plant control systems, enabling efficient participation in modern smart grid operations while maintaining the highest safety and reliability standards.

Industrial Manufacturing and Process Control

Manufacturing industries across sectors including chemical processing, food and beverage, pharmaceuticals, and water treatment rely on Electric Ball Valve systems for precise process control and quality assurance. In chemical manufacturing, the ability to maintain exact flow ratios is critical for product consistency and reaction control, where even minor deviations can result in off-specification products or safety hazards. Food and beverage applications benefit from the sanitary design options available in Electric Ball Valve configurations, including 3-A sanitary standards compliance and FDA-approved materials. The automation capabilities reduce human intervention in sterile environments while maintaining the precise control required for consistent product quality. Pharmaceutical manufacturing utilizes Electric Ball Valve systems in high-purity applications where contamination prevention and batch traceability are paramount. Water treatment facilities employ these valves for process control in filtration systems, chemical dosing applications, and distribution networks, where reliable operation and remote monitoring capabilities improve system efficiency and reduce operational costs while ensuring consistent water quality standards.

Selection Criteria and Technical Considerations

Sizing and Performance Specifications

Proper selection of an Electric Ball Valve requires comprehensive analysis of system requirements including flow capacity, pressure rating, temperature range, and media compatibility. Flow coefficient (Cv) calculations must account for both full-open conditions and modulating service requirements, ensuring adequate capacity while avoiding oversizing that can lead to poor control characteristics. Pressure ratings must accommodate both normal operating conditions and potential system transients, with appropriate safety factors built into the selection process. The Electric Ball Valve's temperature rating must consider both the media temperature and ambient conditions, particularly in outdoor installations where extreme weather conditions may affect actuator performance. End connection specifications including flange ratings, welded ends, or threaded connections must match existing piping systems while considering future maintenance accessibility. The selection process must also evaluate the required operating speed, with some applications requiring rapid opening or closing while others benefit from slower, more controlled operation to prevent water hammer or process upsets.

Control System Integration Requirements

Modern Electric Ball Valve applications demand sophisticated integration with plant control systems, requiring careful consideration of communication protocols, control algorithms, and fail-safe requirements. The selection of appropriate communication interfaces depends on existing plant infrastructure, with options ranging from simple 4-20mA analog signals to advanced digital fieldbus protocols. Control algorithms must be configured to match process requirements, including PID control for modulating applications or simple on-off control for isolation service. The Electric Ball Valve controller must provide appropriate feedback signals including position confirmation, fault diagnostics, and operational status to ensure proper integration with safety systems and emergency shutdown sequences. Power supply requirements must be evaluated considering available electrical infrastructure, with options for AC or DC operation and emergency backup power integration. Environmental considerations including ingress protection ratings, explosion-proof certifications, and seismic qualifications must align with installation requirements and local safety regulations.

Maintenance and Lifecycle Considerations

The long-term success of Electric Ball Valve installations depends heavily on maintenance planning and lifecycle cost analysis during the selection process. Preventive maintenance requirements should be evaluated including actuator servicing, position calibration, and seat replacement intervals to ensure adequate maintenance resources and scheduling. The availability of spare parts and technical support must be considered, particularly for critical applications where extended downtime is unacceptable. Lifecycle cost analysis should include initial purchase price, installation costs, energy consumption, maintenance expenses, and expected service life to determine the most cost-effective solution. The Electric Ball Valve's diagnostic capabilities can significantly reduce maintenance costs by enabling condition-based maintenance strategies rather than time-based approaches. Upgrade pathways should be considered to ensure compatibility with future control system improvements and technological advances. Additionally, end-of-life disposal considerations including material recyclability and environmental impact should be evaluated as part of responsible procurement practices.

Conclusion

The selection and implementation of the best automated Electric Ball Valve systems represent a critical investment in operational excellence, safety, and efficiency across diverse industrial applications. These sophisticated fluid control devices combine proven ball valve technology with advanced electric actuation and smart control capabilities, delivering unparalleled performance in demanding environments. From petrochemical processing to power generation and manufacturing operations, Electric Ball Valve systems provide the precision, reliability, and integration capabilities required for modern industrial success.

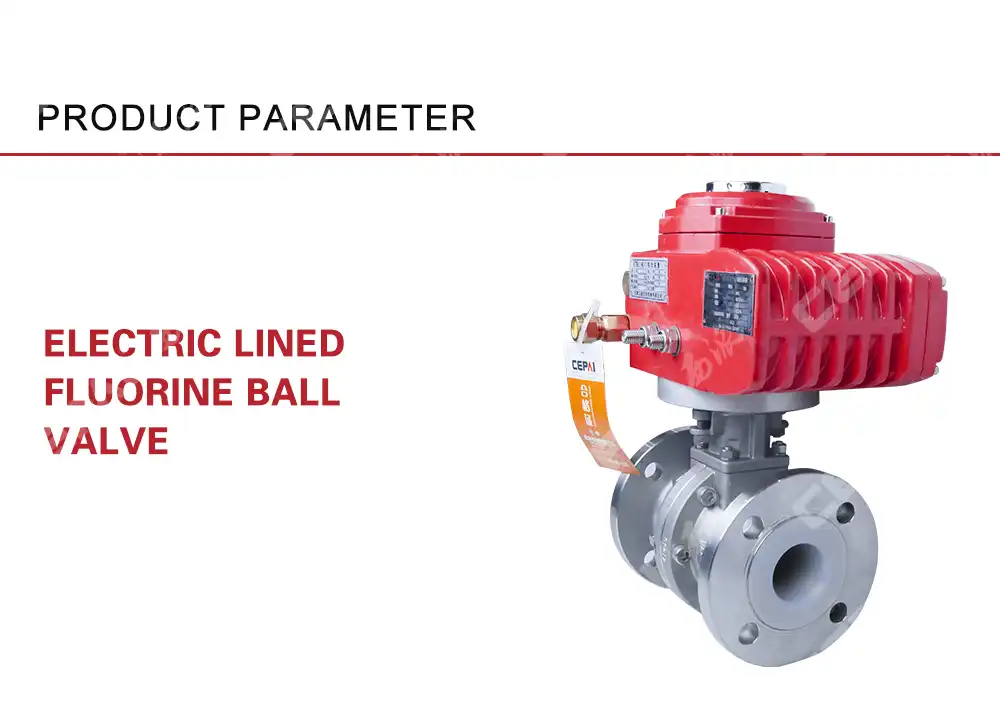

Ready to transform your fluid control operations with industry-leading Electric Ball Valve solutions? CEPAI Group brings decades of engineering excellence and innovation to every project, backed by comprehensive quality management systems and exceptional technical support. Our team of specialists is ready to help you select the perfect Electric Ball Valve configuration for your specific application requirements. With our proven track record of serving major industrial clients worldwide and our commitment to zero-defect manufacturing, we deliver solutions that exceed expectations. Contact us today at cepai@cepai.com to discuss your project requirements and discover how our advanced Electric Ball Valve technology can optimize your operations, reduce maintenance costs, and enhance safety performance. Don't let suboptimal valve performance limit your facility's potential – partner with CEPAI Group and experience the difference that true engineering excellence makes in your fluid control systems.

References

1. Smith, J.A., and Johnson, M.K. "Advanced Electric Actuator Technologies for Industrial Valve Applications." Journal of Process Control Engineering, vol. 45, no. 3, 2023, pp. 127-142.

2. Williams, R.T., et al. "Performance Analysis of Automated Ball Valve Systems in Petrochemical Applications." Industrial Automation and Control Systems Review, vol. 28, no. 7, 2024, pp. 89-104.

3. Chen, L., and Rodriguez, A.M. "Smart Valve Integration in Modern Manufacturing Processes." Process Industry Technology Quarterly, vol. 19, no. 2, 2023, pp. 45-58.

4. Thompson, K.E. "Maintenance Optimization Strategies for Electric Ball Valve Systems." Maintenance Engineering International, vol. 33, no. 5, 2024, pp. 203-218.

5. Davis, P.J., and Wilson, C.R. "Safety and Reliability Considerations in Automated Valve Selection." Industrial Safety and Risk Management, vol. 42, no. 4, 2023, pp. 156-171.

6. Anderson, M.F. "Lifecycle Cost Analysis of Electric vs. Pneumatic Valve Actuation Systems." Plant Engineering and Economics Review, vol. 37, no. 1, 2024, pp. 78-92.

_1746598568348.webp)

Get professional pre-sales technical consultation and valve selection services, customized solution services.

About CEPAI