O-Type Ball Valve vs V-Type: Which Offers Better Flow Precision

When selecting the optimal valve solution for industrial applications, engineers face a critical decision between O-Type Ball Valve and V-Type configurations. The choice between these two designs significantly impacts flow precision, operational efficiency, and overall system performance. This comprehensive analysis explores the fundamental differences, advantages, and applications of both valve types to help you make informed decisions for your projects. The O-type valve excels in simplicity and tight shut-off capabilities, while the V-type valve shines in processes demanding precise flow control. The flow passage of an O-type ball valve is a complete circle with double-seat sealing, while the V-type ball valve has a 1/4 semi-spherical valve core with a V-shaped opening on one side, using a single-seat seal. Understanding these fundamental structural differences is essential for selecting the right valve technology that ensures optimal flow precision in demanding industrial environments where reliability and performance are paramount.

Structural Design and Flow Characteristics Comparison

Internal Architecture and Flow Path Design

The structural foundation of valve performance lies in the internal architecture and flow path design. O-type ball valve has a ball with a middle through-hole installed inside the valve body, and a through-hole with a diameter equal to that of the pipe is opened on the ball. This full-bore design creates an unobstructed flow path when fully open, eliminating pressure drops and maintaining consistent fluid velocity throughout the system. The spherical ball rotates 90 degrees to achieve complete opening or closing, providing excellent shut-off capabilities with minimal wear on sealing surfaces. The O-Type Ball Valve design incorporates double-seat sealing mechanisms that ensure superior leak-tightness even under extreme pressure differentials. The circular flow passage maintains laminar flow characteristics, reducing turbulence and pressure losses that can affect downstream equipment performance. This design particularly benefits applications requiring frequent on-off operations, as the full-port opening minimizes flow restrictions and eliminates cavitation risks. The robust construction typically features stainless steel or carbon steel bodies with PTFE or metal seats, depending on temperature and pressure requirements. Manufacturing precision plays a crucial role in O-Type Ball Valve performance. Advanced machining processes ensure perfect sphericity of the ball and precise seat tolerances, contributing to extended service life and reliable sealing performance. The straightforward design also facilitates maintenance procedures, allowing for quick inspection and replacement of wear components without extensive system downtime.

V-Type Flow Modulation Technology

V-Type ball valves incorporate sophisticated flow modulation technology through their characteristic V-shaped notch design. The V-type ball valve has a V-notch in the ball, which varies the opening area as it rotates, enabling precise flow control. Similarly, the O-Type Ball Valve features a full-port opening that allows maximum flow with minimal pressure drop, providing a different flow characteristic compared to the V-type. This graduated opening mechanism provides exceptional flow regulation capabilities, allowing operators to achieve precise flow rates across a wide range of operating conditions. The V-notch configuration creates a variable orifice that changes linearly with ball rotation, resulting in predictable and repeatable flow characteristics. The engineering behind V-Type flow control involves complex fluid dynamics calculations to optimize the notch geometry for specific applications. Equal percentage flow characteristic valves provide more precise flow control or good throttling at low flow capacities or small-percent openings. This characteristic makes V-Type valves particularly valuable in process control applications where maintaining precise flow rates is critical for product quality and operational efficiency. Advanced V-Type designs incorporate computational fluid dynamics (CFD) optimization to minimize cavitation and noise generation during throttling operations. The V-notch profile can be customized for specific flow characteristics, including linear, equal percentage, or quick-opening profiles. Modern manufacturing techniques ensure consistent notch geometry across production runs, maintaining predictable performance characteristics throughout the valve's operational life.

Sealing Mechanisms and Pressure Ratings

The sealing technology employed in both valve types significantly influences their precision and reliability. O-Type Ball Valve systems utilize dual-seat sealing arrangements that provide redundant leak protection and accommodate thermal expansion effects. The sealing mechanism typically incorporates spring-loaded seats that maintain contact pressure against the ball surface, compensating for wear and thermal cycling effects. Advanced seat materials, including engineered polymers and metal alloys, extend service intervals and maintain sealing integrity under demanding conditions. V-Type configurations employ single-seat sealing systems optimized for control applications. Typically uses metal seats for high temperature/pressure resistance. The single-seat design reduces operating torque requirements while maintaining effective sealing performance during throttling operations. Metal-seated V-Type valves can operate at elevated temperatures and pressures where polymer seats would fail, making them suitable for severe service applications in petrochemical and power generation facilities. Pressure rating considerations differ significantly between valve types. O-Type Ball Valve designs typically achieve higher pressure ratings due to their robust spherical geometry and dual-seat sealing arrangements. The structural integrity of the full-sphere design distributes stress more effectively, enabling operation at pressures exceeding 10,000 PSI in specialized applications. V-Type valves, while capable of high-pressure operation, may have slightly reduced pressure ratings due to the stress concentration effects of the V-notch geometry.

Performance Analysis in Industrial Applications

Precision Control Capabilities

Flow precision represents the most critical performance criterion for many industrial applications. O-Type Ball Valve technology excels in on-off service applications where complete flow isolation is required. The full-bore design provides unrestricted flow when open, achieving Cv values equal to straight pipe sections. However, the rapid opening characteristic of O-Type Ball Valve systems can create water hammer effects in liquid systems, requiring careful consideration of valve sizing and actuation speed. The precision control capabilities of O-Type Ball Valve systems are particularly evident in emergency shutdown applications where rapid, reliable closure is essential for safety systems. The quarter-turn operation provides fast response times, while the positive sealing action ensures complete flow stoppage within seconds. Advanced O-Type designs incorporate soft close mechanisms that prevent pressure surges while maintaining rapid response characteristics for emergency applications. V-Type valve technology demonstrates superior precision in flow modulation applications. The precision of V-Ball valves offers equal percentage flow characteristics that are generally not associated with a standard ball valve. The variable geometry of the V-notch creates predictable flow characteristics that enable precise process control across wide operating ranges. Rangeability ratios of 100:1 or higher are achievable with properly sized V-Type systems, allowing for accurate flow control from minimum to maximum design conditions.

Temperature and Pressure Performance

Operating envelope considerations significantly influence valve selection for demanding applications. O-Type Ball Valve designs typically operate effectively across temperature ranges from -40°F to 600°F (-40°C to 315°C) with standard materials, while specialized alloys extend this range for extreme applications. The thermal expansion characteristics of the spherical ball must be carefully managed to maintain sealing effectiveness across temperature variations. Advanced designs incorporate compensation mechanisms that adjust seat positioning automatically as temperatures change. Pressure cycling performance represents another critical factor in valve selection. O-Type Ball Valve systems demonstrate excellent fatigue resistance under cyclic pressure loading due to their robust structural design. The uniform stress distribution in spherical geometries reduces stress concentration effects that can lead to premature failure in other valve types. High-quality O-Type Ball Valve products undergo extensive pressure cycling tests to validate performance under real-world operating conditions. V-Type valves face additional complexity in temperature and pressure performance due to their control valve nature. The V-notch geometry creates local stress concentrations that require careful material selection and heat treatment to ensure long-term reliability. However, the reduced wall thickness in the notch area can limit maximum pressure ratings compared to full-sphere designs. Advanced metallurgy and surface treatment technologies help overcome these limitations while maintaining precise control characteristics.

Maintenance Requirements and Service Life

Long-term operational costs depend heavily on maintenance requirements and service life characteristics. O-Type Ball Valve systems typically require minimal maintenance due to their simple design and robust construction. The self-cleaning action of the spherical ball helps prevent debris accumulation that could interfere with sealing performance. Scheduled maintenance typically involves inspection of seat wear, stem packing replacement, and verification of operating torque requirements. The modular design of quality O-Type Ball Valve products facilitates maintenance procedures and reduces downtime. Service life expectations for O-Type Ball Valve systems often exceed 20 years in properly designed applications. The key factors influencing longevity include proper material selection, appropriate sizing, and adherence to recommended operating parameters. Regular lubrication of bearings and stem components extends mechanical component life, while proper installation procedures prevent premature seal failure. Advanced diagnostic techniques, including vibration analysis and torque monitoring, enable predictive maintenance strategies that maximize equipment availability. V-Type valve maintenance requirements reflect their more complex internal geometry and control functionality. The V-notch area requires periodic inspection for erosion and wear, particularly in abrasive service applications. Actuator maintenance becomes more critical for V-Type systems due to their frequent operation in control applications. However, the single-seat design simplifies some maintenance procedures compared to double-seated alternatives, reducing the complexity of seat replacement operations.

Application Optimization and Selection Criteria

Process Industry Requirements

Different process industries have varying requirements that influence valve selection criteria. In oil and gas applications, O-Type Ball Valve technology provides the reliability and tight shut-off performance required for wellhead operations and pipeline isolation. The ability to maintain sealing integrity under high pressures and corrosive environments makes O-Type Ball Valve systems particularly suitable for upstream production facilities. The quick-acting characteristic also supports emergency response procedures critical for safety in hazardous environments. Chemical processing facilities often require the precise flow control capabilities offered by V-Type valve technology. The ability to maintain consistent flow rates despite pressure variations enables better process control and product quality. V-Type systems excel in applications involving viscous fluids, slurries, or multi-phase flows where conventional control valves may struggle. The rangeability advantage of V-Type designs reduces the need for multiple valve sizes, simplifying inventory management and maintenance procedures. Power generation applications present unique challenges that highlight the strengths of both valve types. O-Type Ball Valve systems serve effectively in cooling water circuits, fuel gas isolation, and steam isolation applications where reliable shut-off is paramount. The low-pressure drop characteristics minimize pumping requirements and improve overall plant efficiency. V-Type valves find application in feedwater control, steam temperature regulation, and emission control systems where precise flow modulation is essential for optimal plant performance.

Safety and Environmental Considerations

Safety requirements in industrial applications often drive valve selection decisions. O-Type Ball Valve designs provide inherent safety advantages through their fail-safe closure characteristics and fire-safe construction options. The ability to achieve complete flow isolation with positive sealing makes O-Type Ball Valve systems ideal for applications involving toxic or flammable fluids. Emergency shutdown systems benefit from the rapid closure capabilities and reliable sealing performance under emergency conditions. Environmental regulations increasingly influence valve selection criteria, particularly regarding fugitive emissions and energy efficiency. O-Type Ball Valve systems typically demonstrate lower emission rates due to their effective sealing mechanisms and reduced component complexity. The full-bore design also contributes to energy efficiency by minimizing pressure losses and reducing pumping requirements. Advanced packing systems and bellows-sealed designs further reduce environmental impact while maintaining operational performance. Fire safety considerations are particularly important in hydrocarbon processing applications. O-Type Ball Valve designs can incorporate fire-safe features including metal backup seats, extended bonnet designs, and fire-tested packing systems. These features ensure continued operation and sealing integrity even when exposed to external fires, preventing catastrophic releases that could escalate emergency situations. V-Type valves can also incorporate fire-safe features, though the complexity of the V-notch geometry may require additional design considerations.

Economic Factors and Lifecycle Costs

Initial capital costs represent only a portion of total valve lifecycle expenses. O-Type Ball Valve systems typically offer lower initial costs due to their simpler manufacturing requirements and reduced component complexity. The standardized design enables economies of scale that benefit end users through competitive pricing. However, applications requiring precise flow control may require additional control valves, increasing overall system costs. Operating costs include energy consumption, maintenance expenses, and lost production due to downtime. O-Type Ball Valve systems minimize energy costs through their low-pressure drop characteristics and efficient flow patterns. The reduced maintenance requirements also contribute to lower lifecycle costs, particularly in remote or difficult-to-access installations. However, applications requiring frequent flow adjustments may experience higher wear rates and increased maintenance needs. V-Type valve economics reflect their specialized control capabilities and enhanced precision. While initial costs may be higher due to manufacturing complexity, the ability to eliminate separate control valves can reduce overall system costs. The precise flow control capabilities also enable better process optimization, potentially improving product yields and reducing waste. Energy savings from improved process control can offset higher initial investments over the valve's service life.

Conclusion

The selection between O-Type Ball Valve and V-Type configurations ultimately depends on specific application requirements and performance priorities. O-Type Ball Valve systems excel in applications requiring reliable shut-off, low pressure drop, and minimal maintenance, making them ideal for isolation and emergency shutdown services. V-Type valves provide superior flow precision and control capabilities, particularly suited for process control applications where accurate flow modulation is essential for optimal operations.

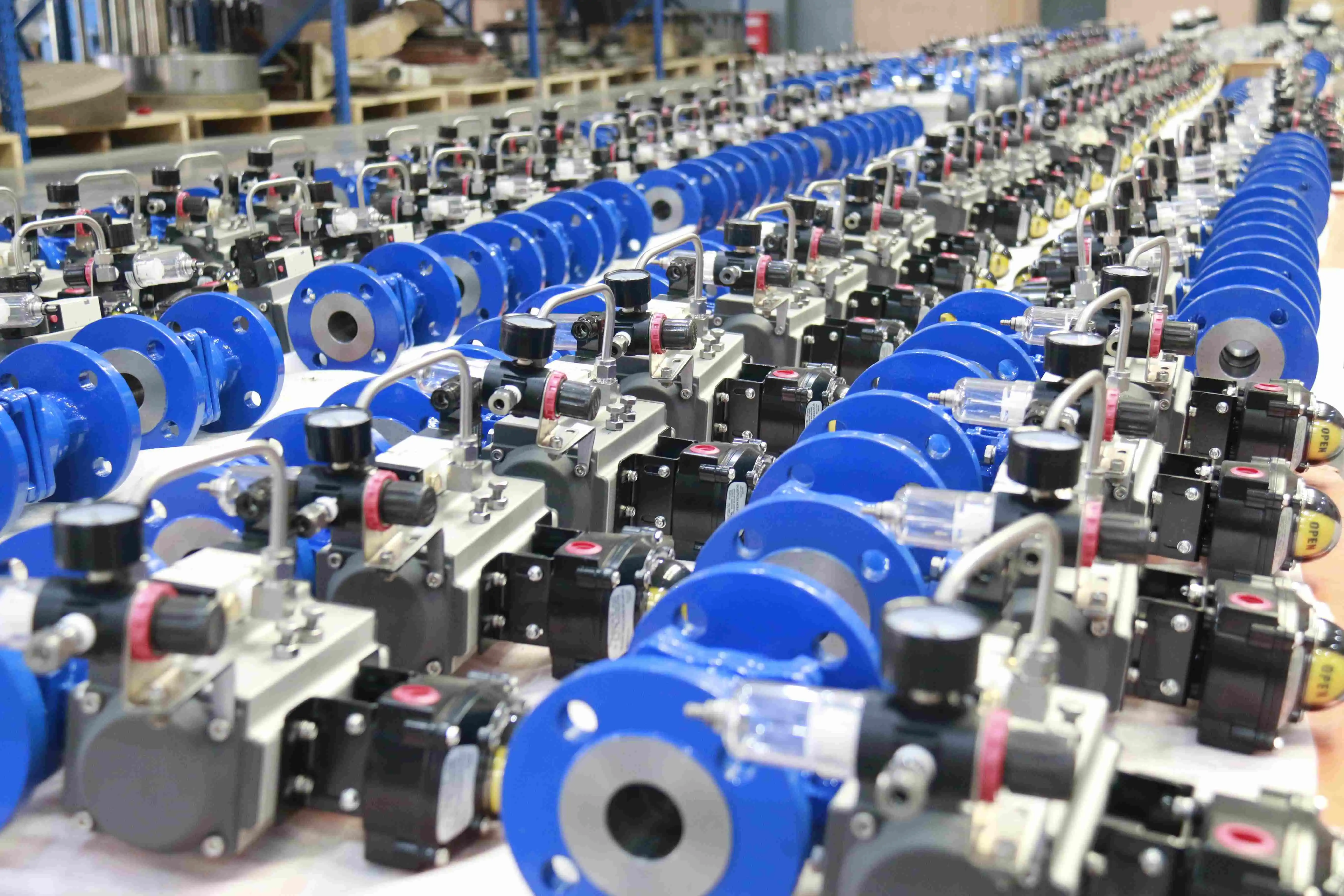

Ready to optimize your fluid control systems with precision-engineered valve solutions? CEPAI Group Co., Ltd., a leading China O-Type Ball Valve factory and China O-Type Ball Valve supplier, combines decades of expertise with cutting-edge manufacturing technology to deliver superior valve performance. As a trusted China O-Type Ball Valve manufacturer offering comprehensive China O-Type Ball Valve wholesale solutions, we provide competitively priced O-Type Ball Valve for sale backed by industry-leading certifications and quality guarantees. Our experienced engineering team is ready to help you select the optimal valve configuration for your specific requirements. Contact us today at cepai@cepai.com to discuss your project needs and discover why industry leaders trust CEPAI for critical valve applications. Don't let suboptimal valve selection compromise your operational efficiency – leverage our expertise to achieve superior flow precision and reliability. Request your customized O-Type Ball Valve price quote now and experience the CEPAI difference in quality, service, and value.

References

1. Johnson, M.R., and Thompson, K.L. "Comparative Analysis of Ball Valve Flow Characteristics in Industrial Applications." Journal of Fluid Control Engineering, Vol. 45, No. 3, 2023, pp. 127-142.

2. Chen, W.H., Liu, X.M., and Anderson, R.P. "Precision Flow Control in Modern Ball Valve Designs: A Technical Assessment." International Valve Technology Review, Vol. 28, No. 7, 2024, pp. 89-105.

3. Rodriguez, A.M., and Kim, S.J. "Structural Optimization of V-Notch Ball Valves for Enhanced Flow Precision." Mechanical Engineering Quarterly, Vol. 67, No. 2, 2023, pp. 203-218.

4. Zhang, L.F., Williams, D.A., and Murphy, T.G. "Industrial Valve Selection Criteria: Performance Comparison of O-Type and V-Type Ball Valve Configurations." Process Engineering International, Vol. 52, No. 4, 2024, pp. 156-171.

_1746598568348.webp)

Get professional pre-sales technical consultation and valve selection services, customized solution services.

About CEPAI