Maximizing Reliability: A Guide to Your Pneumatic Ball Valve

When your production line suddenly shuts down due to valve failure, costing thousands per hour in lost productivity, you realize that maximizing reliability of your Pneumatic Ball Valve isn't just about maintenance—it's about safeguarding your entire operation. This comprehensive guide delivers proven strategies to optimize your Pneumatic Ball Valve performance, extend operational lifespan, and prevent costly downtime through systematic maintenance approaches, advanced monitoring techniques, and industry-leading best practices that transform reactive repairs into proactive reliability management.

Understanding Pneumatic Ball Valve Fundamentals

-

Core Components and Operating Principles

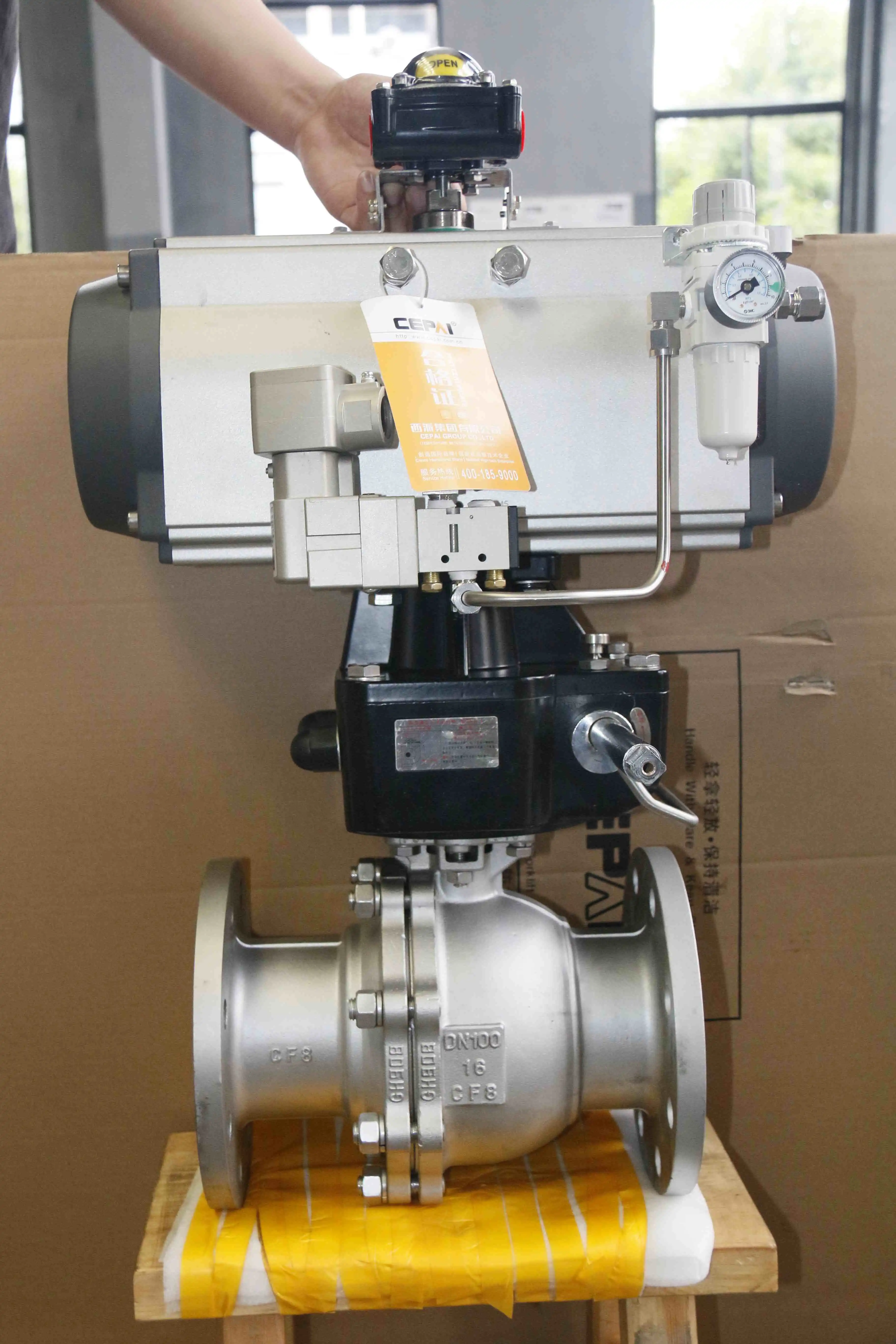

Pneumatic Ball Valve systems represent the pinnacle of automated flow control technology, combining mechanical precision with pneumatic power to deliver reliable operation across diverse industrial applications. The fundamental architecture consists of a spherical closure element—the ball—positioned within a valve body, controlled by a pneumatic actuator that harnesses compressed air to achieve rapid, precise positioning. This design philosophy prioritizes both operational efficiency and maintenance accessibility, making Pneumatic Ball Valve solutions ideal for applications demanding consistent performance under varying pressure and temperature conditions. The actuator mechanism converts pneumatic pressure into rotational motion, typically providing 90-degree quarter-turn operation that moves the ball from fully open to fully closed position. Modern Pneumatic Ball Valve designs incorporate advanced sealing technologies, including PTFE seats and O-ring configurations, ensuring tight shut-off capabilities even under extreme service conditions. The integration of position feedback systems enables real-time monitoring of valve status, supporting predictive maintenance strategies that maximize equipment reliability while minimizing operational disruptions.

-

Material Selection and Construction Standards

Material compatibility represents a critical factor in Pneumatic Ball Valve reliability, directly impacting service life and maintenance requirements. Stainless steel bodies provide exceptional corrosion resistance for chemical processing applications, while carbon steel construction offers cost-effective solutions for standard industrial services. The ball and seat materials must withstand both mechanical stress and chemical exposure, with options ranging from hardened stainless steel to specialized alloys designed for specific media compatibility requirements. Construction standards define the reliability foundation of every Pneumatic Ball Valve installation. API 6D certification ensures compliance with petroleum industry requirements, while ISO 9001 quality management systems guarantee consistent manufacturing processes. Advanced manufacturing techniques, including precision machining and automated assembly procedures, contribute to dimensional accuracy that directly translates to improved sealing performance and extended operational life. Quality control protocols encompass material traceability, pressure testing, and performance validation to ensure each Pneumatic Ball Valve meets stringent reliability standards.

Critical Maintenance Strategies for Maximum Reliability

-

Preventive Maintenance Protocols

Systematic preventive maintenance forms the cornerstone of Pneumatic Ball Valve reliability optimization. Regular inspection schedules must address both mechanical components and pneumatic systems, identifying potential issues before they escalate into operational failures. Visual inspection procedures focus on actuator mounting integrity, air line connections, and external seal conditions, while operational testing verifies response times and positioning accuracy. Documentation of maintenance activities creates historical records that support trend analysis and predictive maintenance decision-making. Lubrication management represents another crucial aspect of Pneumatic Ball Valve maintenance reliability. Proper lubricant selection based on operating temperature, pressure, and media compatibility ensures optimal actuator performance while preventing premature wear. Scheduled lubrication intervals must account for service severity, with high-cycle applications requiring more frequent attention than intermittent duty installations. Advanced synthetic lubricants offer extended service intervals and improved performance characteristics, contributing to overall system reliability through reduced maintenance requirements and enhanced component protection.

-

Advanced Monitoring and Diagnostic Techniques

Modern reliability strategies incorporate sophisticated monitoring technologies that enable condition-based maintenance approaches for Pneumatic Ball Valve systems. Vibration analysis detects mechanical wear patterns in actuator components, while pressure monitoring identifies pneumatic system inefficiencies that could impact valve performance. Temperature sensors provide early warning of excessive friction or pneumatic system anomalies, enabling proactive intervention before component failure occurs. Digital diagnostic systems integrate multiple monitoring parameters to provide comprehensive health assessment capabilities for Pneumatic Ball Valve installations. Real-time data collection enables trend analysis that identifies gradual performance degradation, supporting optimized maintenance scheduling that maximizes equipment availability while minimizing maintenance costs. Remote monitoring capabilities allow centralized oversight of distributed valve populations, enabling expert analysis and coordinated maintenance planning across multiple facility locations.

Operational Optimization Techniques

-

Performance Enhancement Strategies

Optimizing Pneumatic Ball Valve performance requires systematic evaluation of operating parameters and environmental conditions. Air supply quality directly impacts actuator reliability, with proper filtration and pressure regulation preventing contamination-related failures and ensuring consistent operation. Supply pressure optimization balances response speed with actuator longevity, while proper sizing ensures adequate torque margins for reliable operation under varying process conditions. Environmental protection measures significantly enhance Pneumatic Ball Valve reliability in challenging service conditions. Actuator enclosures provide protection from weather exposure, while heating systems prevent freeze-up in cold climate installations. Vibration isolation reduces mechanical stress from external sources, while proper mounting techniques minimize alignment issues that could cause premature wear or binding conditions affecting valve performance.

-

System Integration and Control Optimization

Control system integration plays a vital role in maximizing Pneumatic Ball Valve reliability through optimized operating sequences and protective logic. Soft start algorithms reduce mechanical stress during valve actuation, while position feedback enables precise control that minimizes wear on seats and seals. Emergency shutdown sequences protect equipment from damage during abnormal conditions, while diagnostic feedback supports maintenance planning and troubleshooting activities. Advanced control strategies incorporate predictive algorithms that optimize valve operation based on process requirements and equipment condition. Variable speed actuation reduces water hammer effects in liquid services, while staged opening sequences manage pressure differentials that could cause cavitation or excessive mechanical stress. Integration with plant-wide control systems enables coordinated operation that optimizes both process performance and equipment reliability across entire facility operations.

Troubleshooting and Problem Resolution

-

Common Failure Modes and Solutions

Understanding typical Pneumatic Ball Valve failure patterns enables proactive maintenance strategies that prevent unexpected downtime. Actuator failures often result from contaminated air supply, inadequate lubrication, or excessive cycling beyond design limits. Seat leakage typically stems from debris accumulation, thermal cycling effects, or improper installation procedures that create alignment issues affecting sealing performance. Systematic diagnostic approaches facilitate rapid problem identification and resolution. Pressure decay testing isolates internal leakage issues, while stroke timing analysis identifies actuator performance degradation. Visual inspection techniques reveal external damage or wear patterns, while operational testing verifies proper response to control signals and manual override functions.

-

Emergency Response and Rapid Recovery

Emergency response procedures minimize the impact of Pneumatic Ball Valve failures on overall plant operations. Manual override capabilities provide immediate flow control restoration while repairs are planned and executed. Spare parts inventory management ensures critical components are available for rapid replacement, while cross-training maintenance personnel enables 24/7 response capabilities that minimize downtime duration. Recovery strategies emphasize systematic approaches that address root causes rather than temporary fixes. Post-failure analysis identifies contributing factors that inform preventive maintenance improvements, while documentation supports continuous improvement initiatives. Vendor support coordination ensures access to technical expertise and specialized replacement parts that may be required for complex repair activities.

Industry Applications and Best Practices

-

Sector-Specific Reliability Requirements

Different industrial sectors impose unique reliability requirements on Pneumatic Ball Valve installations. Petroleum and petrochemical applications demand explosion-proof actuators and specialized materials that withstand aggressive media and extreme temperatures. Power generation facilities require rapid response capabilities and high-cycle durability to support frequent load changes and emergency shutdown requirements. Water and wastewater treatment applications emphasize corrosion resistance and environmental protection, while food and pharmaceutical industries require sanitary designs that support frequent cleaning and sterilization procedures. Manufacturing facilities focus on production continuity and integration with automated systems, requiring reliable position feedback and diagnostic capabilities that support predictive maintenance programs.

-

Technology Integration and Future Trends

Emerging technologies continue to enhance Pneumatic Ball Valve reliability through advanced materials, improved manufacturing processes, and sophisticated monitoring systems. Smart actuators incorporate embedded sensors and processing capabilities that enable autonomous health monitoring and predictive maintenance recommendations. Digital twin technologies support virtual modeling and simulation that optimizes maintenance strategies and predicts equipment performance under varying operating conditions. Wireless communication capabilities eliminate hard-wired installation requirements while providing real-time status information to centralized control systems. Artificial intelligence applications analyze operational data patterns to identify optimal maintenance intervals and predict potential failure scenarios, enabling proactive interventions that maximize equipment reliability while minimizing maintenance costs and operational disruptions.

Conclusion

Maximizing reliability of your Pneumatic Ball Valve requires a comprehensive approach combining proper selection, systematic maintenance, advanced monitoring, and proactive troubleshooting strategies that address both immediate operational needs and long-term performance optimization goals through continuous improvement.

Cooperate with CEPAI Group Co., LTD.

CEPAI Group Co., LTD. stands as China's premier Pneumatic Ball Valve manufacturer, combining advanced intelligent manufacturing capabilities with decades of specialized expertise in high-performance valve solutions. Since our establishment in 2009, we have invested 156 million yuan in cutting-edge production facilities, creating the Asia Pacific region's longest high-precision intelligent manufacturing flexible production line. Our comprehensive certification portfolio, including API 6A, ISO 9001, and CE marking, demonstrates our commitment to international quality standards and regulatory compliance.

As a leading China Pneumatic Ball Valve factory, we serve major industry clients including PetroChina, Sinopec, and CNOOC, delivering customized solutions that maximize operational reliability across diverse applications. Our China Pneumatic Ball Valve supplier network extends globally, supported by advanced remote monitoring systems and AR-guided maintenance services that enhance customer satisfaction and equipment performance. Whether you need a trusted China Pneumatic Ball Valve manufacturer for standard applications or require specialized High Quality Pneumatic Ball Valve solutions, our engineering team provides comprehensive pre-sales consultation, customized design services, and complete after-sales support.

Discover competitive Pneumatic Ball Valve price options and explore our extensive Pneumatic Ball Valve for sale inventory through our streamlined quotation process. Partner with CEPAI Group for China Pneumatic Ball Valve wholesale opportunities that combine exceptional value with proven reliability. Contact our technical specialists at cepai@cepai.com to discuss your specific requirements and experience the CEPAI advantage in precision valve technology.

FAQ

Q: How often should pneumatic ball valves be inspected for optimal reliability?

A: Pneumatic ball valves should undergo visual inspection monthly, with comprehensive performance testing quarterly and detailed maintenance annually, adjusted based on service severity and operating cycles.

Q: What are the most common causes of pneumatic ball valve failure?

A: The primary failure causes include contaminated air supply, inadequate lubrication, seat wear from debris or cycling, and actuator component fatigue from excessive operational frequency.

Q: How can I extend the service life of my pneumatic ball valve?

A: Regular maintenance, proper air filtration, appropriate lubrication, environmental protection, and operating within design parameters significantly extend valve service life and reliability.

Q: What diagnostic tools are most effective for monitoring pneumatic ball valve performance?

A: Effective diagnostic tools include pressure monitoring systems, stroke timing analyzers, vibration sensors, temperature monitoring, and digital position feedback systems for comprehensive health assessment.

References

1. "Pneumatic Control Systems: Design and Operation Guidelines" - Industrial Automation Institute, Technical Publication Series

2. "Ball Valve Engineering Handbook: Materials, Design, and Performance" - American Society of Mechanical Engineers Standards Committee

3. "Reliability Engineering in Process Industries: Valve Systems Analysis" - International Association of Process Equipment Manufacturers

4. "Advanced Maintenance Strategies for Industrial Valve Systems" - National Institute for Occupational Safety and Health Engineering Division

_1746598568348.webp)

Get professional pre-sales technical consultation and valve selection services, customized solution services.

About CEPAI