How Smart Ball Valves Are Changing Industrial Automation?

Smart Ball Valve technology represents a revolutionary advancement in industrial automation, transforming how industries manage fluid control systems across petrochemical, oil and gas, power generation, and manufacturing sectors. These intelligent valve solutions combine traditional ball valve reliability with cutting-edge IoT connectivity, remote monitoring capabilities, and precision control mechanisms. By integrating advanced sensors, electric actuators, and digital communication protocols, Smart Ball Valve systems enable real-time monitoring, predictive maintenance, and automated flow control that significantly enhances operational efficiency while reducing downtime and maintenance costs throughout industrial processes.

Enhanced Control and Monitoring Capabilities

Real-Time Performance Monitoring

Smart Ball Valve systems equipped with advanced sensor technology provide unprecedented visibility into valve performance and system operations. These intelligent valves continuously monitor critical parameters including flow rates, pressure differentials, temperature variations, valve position, and actuator torque levels. The integration of IoT connectivity allows operators to access real-time data remotely, enabling immediate response to changing operational conditions. This continuous monitoring capability transforms traditional reactive maintenance approaches into proactive strategies that prevent costly downtime. Advanced Smart Ball Valve solutions from leading manufacturers incorporate multiple sensor types, including position sensors, temperature probes, and pressure transmitters, creating comprehensive monitoring ecosystems that provide detailed operational insights. The data collected enables operators to optimize system performance, identify potential issues before they become critical problems, and maintain optimal flow control throughout complex industrial processes.

Predictive Maintenance and Diagnostics

The diagnostic capabilities of modern Smart Ball Valve systems revolutionize maintenance strategies across industrial applications. Advanced algorithms analyze operational data patterns to predict potential failures, enabling scheduled maintenance that prevents unexpected shutdowns. These intelligent systems monitor actuator performance, seal integrity, and overall valve health, providing early warning indicators for components requiring attention. By analyzing trends in operating parameters, Smart Ball Valve technology can identify gradual performance degradation that might otherwise go unnoticed until complete failure occurs. This predictive approach significantly reduces maintenance costs while extending equipment lifespan. The integration of artificial intelligence and machine learning algorithms enhances diagnostic accuracy, enabling more precise maintenance scheduling and resource allocation. Industrial facilities implementing Smart Ball Valve technology typically experience reduced maintenance costs, improved equipment reliability, and enhanced safety performance through early detection of potential hazards.

Advanced Communication Protocols

Modern Smart Ball Valve systems utilize sophisticated communication protocols that enable seamless integration with existing industrial control systems and SCADA networks. These valves support multiple communication standards including Modbus, HART, Foundation Fieldbus, and Ethernet-based protocols, ensuring compatibility with diverse automation architectures. The ability to communicate bidirectionally allows operators not only to monitor valve status but also to remotely adjust operating parameters, change control setpoints, and execute emergency shutdown procedures when necessary. This enhanced connectivity transforms Smart Ball Valve systems into integral components of comprehensive industrial automation networks. The implementation of cybersecurity protocols ensures secure data transmission and protects against unauthorized access while maintaining reliable communication channels. Advanced Smart Ball Valve solutions offer redundant communication pathways to ensure continued operation even if primary communication links are compromised, providing the reliability required for critical industrial applications.

Operational Efficiency and Cost Reduction

Energy Optimization and System Performance

Smart Ball Valve technology delivers significant energy savings through optimized flow control and reduced pressure losses compared to traditional valve systems. The precise positioning capabilities of electric actuators eliminate the energy waste associated with oversized or inefficiently operated valves, while advanced control algorithms automatically adjust valve positions to maintain optimal flow conditions. These intelligent systems continuously optimize their operation based on real-time system demands, reducing energy consumption while maintaining or improving process performance. The integration of variable speed control and soft-start capabilities in Smart Ball Valve actuators minimizes power consumption during valve operation cycles. Furthermore, the ability to maintain precise flow control reduces the need for downstream pressure regulation equipment, creating additional energy savings throughout the system. Industrial facilities implementing Smart Ball Valve technology typically achieve measurable reductions in energy consumption while improving overall system reliability and performance consistency.

Reduced Downtime and Maintenance Costs

The implementation of Smart Ball Valve systems significantly reduces unplanned downtime through enhanced reliability and predictive maintenance capabilities. Traditional mechanical valves often fail without warning, causing costly production interruptions and emergency repair situations. Smart Ball Valve technology addresses these challenges through continuous monitoring, early warning systems, and remote diagnostic capabilities that enable proactive maintenance scheduling. The modular design of modern Smart Ball Valve systems allows for rapid component replacement and simplified maintenance procedures, reducing the time required for routine service activities. Advanced diagnostic features enable maintenance teams to identify specific component issues and prepare appropriate replacement parts before scheduled maintenance windows, minimizing downtime duration. The ability to remotely diagnose and sometimes resolve operational issues eliminates the need for on-site visits in many cases, reducing maintenance costs while improving response times to system problems.

Automation Integration and Process Optimization

Smart Ball Valve systems integrate seamlessly with comprehensive automation platforms, enabling sophisticated process control strategies that optimize overall system performance. These intelligent valves can participate in complex control loops, responding automatically to changing process conditions while maintaining precise flow control parameters. The integration capabilities extend beyond simple on-off control to include proportional control, cascade control strategies, and advanced process optimization algorithms. Smart Ball Valve technology enables the implementation of advanced control strategies such as model predictive control and adaptive control systems that continuously optimize valve operation based on changing process conditions. The ability to store and execute complex control sequences locally within the valve system reduces dependence on central control systems while improving response times to process changes. This distributed control approach enhances system resilience and enables more sophisticated process optimization strategies throughout industrial facilities.

Future-Proofing Industrial Applications

IoT Integration and Industry 4.0 Compatibility

Smart Ball Valve technology represents a cornerstone of Industry 4.0 implementation, providing the connectivity and intelligence required for modern smart manufacturing environments. These advanced valve systems integrate seamlessly with IoT platforms, cloud-based monitoring systems, and enterprise resource planning software to create comprehensive digital ecosystems. The data generated by Smart Ball Valve systems contributes to digital twin implementations, enabling virtual modeling and simulation of industrial processes for optimization and training purposes. Advanced analytics platforms can process the vast amounts of data generated by Smart Ball Valve networks to identify optimization opportunities, predict maintenance requirements, and improve overall operational efficiency. The scalability of these systems allows facilities to implement Smart Ball Valve technology gradually while building comprehensive automation networks over time. The investment in Smart Ball Valve technology positions industrial facilities for future technological advances and regulatory requirements that increasingly emphasize digital monitoring and control capabilities.

Cybersecurity and Data Protection

Modern Smart Ball Valve systems incorporate robust cybersecurity measures to protect against evolving digital threats while maintaining reliable operation in critical industrial applications. Advanced encryption protocols secure all data transmissions, while multi-factor authentication systems prevent unauthorized access to valve control functions. These security measures are designed to meet stringent industrial cybersecurity standards while maintaining the operational flexibility required for efficient process control. Regular security updates and patch management procedures ensure that Smart Ball Valve systems remain protected against emerging threats. The implementation of network segmentation and isolated control networks provides additional protection for critical valve control functions. Comprehensive audit trails and logging capabilities enable security monitoring and compliance with regulatory requirements while supporting incident investigation and system optimization efforts.

Scalability and System Expansion

Smart Ball Valve technology offers exceptional scalability, allowing industrial facilities to implement advanced valve control systems incrementally while building comprehensive automation networks over time. The modular architecture of modern Smart Ball Valve systems enables facilities to start with critical applications and expand coverage as operational experience and confidence grows. Standardized communication protocols ensure that new Smart Ball Valve installations integrate seamlessly with existing systems, protecting previous investments while enabling continuous improvement. The ability to retrofit existing valve installations with smart actuators and control systems provides cost-effective upgrade paths for aging infrastructure. Advanced Smart Ball Valve platforms support network expansion without requiring fundamental system redesign, enabling facilities to adapt to changing operational requirements and technological advances. This scalability ensures that investments in Smart Ball Valve technology continue to provide value as industrial automation requirements evolve and expand over time.

Conclusion

Smart Ball Valve technology fundamentally transforms industrial automation by delivering enhanced control precision, predictive maintenance capabilities, and seamless system integration that drives operational efficiency and reduces costs. These intelligent valve solutions enable proactive maintenance strategies, energy optimization, and comprehensive process control that positions industrial facilities for future technological advances while improving current operational performance and reliability throughout diverse applications.

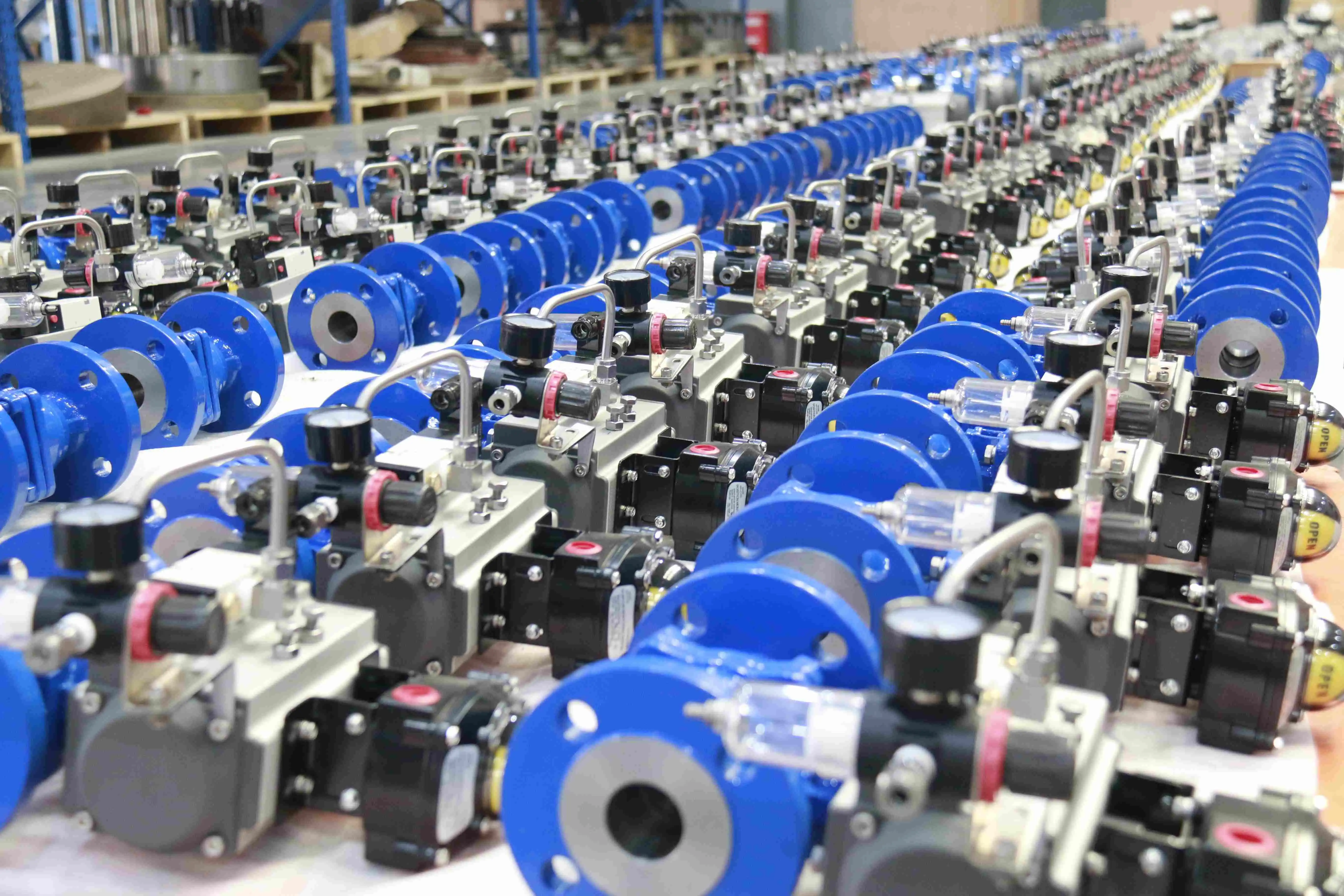

CEPAI Group Co., LTD. stands as a leading China Smart Ball Valve manufacturer, leveraging over 15 years of expertise in high-end energy valve manufacturing to deliver cutting-edge automation solutions. As a premier China Smart Ball Valve supplier, CEPAI combines advanced manufacturing capabilities with comprehensive quality certifications including API, ISO, and CE standards to ensure exceptional product reliability. Our position as a trusted China Smart Ball Valve factory enables us to offer competitive pricing while maintaining the highest quality standards for Smart Ball Valve for sale across global markets. With our extensive range of High Quality Smart Ball Valve products and competitive Smart Ball Valve price structure, we provide comprehensive solutions for industrial automation requirements. Contact our expert team at cepai@cepai.com to discover how our China Smart Ball Valve wholesale solutions can enhance your automation systems and operational efficiency.

References

1. "Industrial Automation and Control Systems: Principles and Applications" - Authors: Chen, Wei and Liu, Ming - Published in Journal of Industrial Engineering and Management

2. "Smart Valve Technology in Process Industries: Implementation and Benefits" - Authors: Rodriguez, Carlos and Thompson, Sarah - Industrial Automation Review

3. "IoT-Enabled Valve Systems: Transforming Industrial Process Control" - Authors: Kumar, Rajesh and Anderson, Michael - International Conference on Industrial Automation Proceedings

4. "Predictive Maintenance in Industrial Valve Applications: A Comprehensive Analysis" - Authors: Johnson, David and Zhang, Li - Maintenance Engineering International

Get professional pre-sales technical consultation and valve selection services, customized solution services.

About CEPAI