Electric Valve Certifications You Should Ask Suppliers For

When sourcing electric valves for industrial applications, understanding the essential certifications your suppliers should possess is crucial for ensuring safety, reliability, and regulatory compliance. Electric valve certifications serve as quality assurance markers that demonstrate a manufacturer's commitment to international standards and rigorous testing protocols. These certifications not only protect your investment but also ensure operational safety in critical applications across petrochemical, power generation, and fluid control systems. By demanding proper certifications from suppliers, procurement professionals can mitigate risks, ensure compliance with local regulations, and guarantee that their electric valve systems will perform reliably under demanding industrial conditions. The certification landscape for electric valves encompasses multiple international standards, each addressing specific aspects of design, manufacturing, testing, and performance verification.

Essential International Standards for Electric Valve Procurement

Understanding the fundamental certification requirements is the first step in establishing reliable supplier relationships for electric valve procurement. International standards provide the framework for quality assurance, safety protocols, and performance benchmarks that distinguish professional manufacturers from substandard suppliers.

API Certification Requirements for Electric Valves

The American Petroleum Institute (API) certification represents the gold standard for electric valve applications in oil and gas industries. API-certified ball valve, including the pneumatic ball valve variant, demonstrates compliance with rigorous industry-specific requirements. API certifications such as API 6A, API 6D, and API 602 ensure that electric valves can withstand extreme pressures, temperatures, and corrosive environments typical in petroleum applications. These certifications require extensive testing protocols including pressure testing, material verification, and dimensional accuracy checks. Electric valve manufacturers must demonstrate their manufacturing processes meet API standards through regular audits and quality control procedures. The API certification process involves third-party verification of design specifications, manufacturing capabilities, and quality management systems. For electric control valves used in wellhead applications, API 6A certification specifically addresses the unique challenges of high-pressure, high-temperature environments where valve failure could result in catastrophic consequences. Electric valve suppliers should provide documentation showing their API certification scope, validity periods, and specific product lines covered under these certifications.

ISO Quality Management Certifications

ISO certifications form the backbone of international quality management for electric valve manufacturing. ISO 9001 quality management certification ensures suppliers maintain consistent quality control processes throughout their electric valve production cycles. ISO 14001 environmental management certification demonstrates the supplier's commitment to sustainable manufacturing practices, which is increasingly important for corporate social responsibility requirements. ISO 45001 occupational health and safety certification indicates that the electric valve manufacturer prioritizes worker safety and maintains safe manufacturing environments. These ISO certifications require continuous improvement processes, regular internal audits, and external verification by accredited certification bodies. Electric valve suppliers with comprehensive ISO certifications typically demonstrate better supply chain reliability, consistent product quality, and professional management systems. The integration of these ISO standards creates a robust framework for electric valve manufacturing that addresses quality, environmental impact, and workplace safety simultaneously. When evaluating electric valve suppliers, procurement professionals should verify the currency and scope of all ISO certifications to ensure they cover the specific products being sourced.

ASME and Pressure Vessel Code Compliance

The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code compliance is essential for electric valves used in pressure vessel applications. The ASME Certification Mark indicates that a device is in compliance with the ASM Boiler and Pressure Vessel Codes (BPVCs), ensuring electric valves meet stringent safety requirements for high-pressure applications. ASME certification requires electric valve manufacturers to demonstrate their design, manufacturing, and testing capabilities meet or exceed code requirements. This certification is particularly critical for electric valves used in power generation, chemical processing, and other applications where pressure vessel safety is paramount. The ASME certification process includes material verification, design review, manufacturing quality control, and testing procedures that ensure electric valves can safely operate within their specified pressure and temperature ranges. Electric valve suppliers must maintain authorized inspector oversight during manufacturing and testing phases to ensure ASME compliance. The certification also requires proper documentation, including material test reports, pressure test certificates, and dimensional inspection records for each electric valve produced under ASME codes.

Safety and Performance Certifications for Electric Valve Applications

Safety certifications represent critical risk management tools for electric valve procurement, ensuring that suppliers meet international safety standards and performance requirements. These certifications address both electrical safety and mechanical performance aspects of electric valve systems.

CE Marking and European Safety Standards

CE marking is mandatory for electric valves sold within the European Economic Area and represents conformity with European safety, health, and environmental protection standards. CE, RoHS 3, UL, CSA, and NSF, and ensure your solenoid valves meet industry standards for safety and compliance are essential certifications for global market access. The CE marking process for electric valves involves comprehensive testing of electrical components, electromagnetic compatibility, and mechanical safety features. Electric valve manufacturers must conduct risk assessments, prepare technical documentation, and ensure their products meet relevant European directives including the Machinery Directive and Electromagnetic Compatibility Directive. The CE certification process requires detailed technical files documenting design specifications, test results, and quality control procedures for electric valve production. This certification ensures that electric valves meet European Union safety requirements for electrical equipment, protecting end users from electrical hazards and ensuring reliable operation in industrial environments. Electric valve suppliers must maintain continuous compliance with CE requirements, including regular testing and documentation updates to reflect any design or manufacturing changes.

SIL (Safety Integrity Level) Certifications

Safety Integrity Level (SIL) certifications are crucial for electric valves used in safety-critical applications where valve failure could result in hazardous situations. SIL certifications evaluate the probability of dangerous failures and the ability of electric valve systems to perform their safety functions when demanded. Electric valve manufacturers must demonstrate their products meet specific SIL ratings through rigorous testing protocols, failure mode analysis, and reliability calculations. The SIL certification process includes comprehensive testing of electric actuators, control systems, and valve body components to ensure integrated system safety performance. For electric control valves, SIL certification validates the entire system's ability to fail safely and maintain process safety integrity. This certification requires detailed documentation of failure rates, testing procedures, and quality management systems specific to safety-critical electric valve applications. Electric valve suppliers should provide SIL certificates that clearly specify the certified SIL level, application boundaries, and maintenance requirements to maintain certified performance levels.

UL and CSA Electrical Safety Certifications

Underwriters Laboratories (UL) and Canadian Standards Association (CSA) certifications ensure electric valve electrical components meet North American safety standards. These certifications address electrical safety concerns including overcurrent protection, insulation integrity, and electromagnetic interference resistance for electric valve systems. UL certification requires comprehensive testing of electrical components, including electric actuators, control circuits, and power supply systems used in electric valve applications. The certification process evaluates electrical safety under normal operating conditions and fault scenarios to ensure electric valves do not pose electrical hazards to personnel or equipment. CSA certification provides similar assurance for Canadian market applications, ensuring electric valves meet Canadian electrical safety codes and standards. Electric valve suppliers must maintain current UL and CSA certifications through regular factory inspections and product testing to ensure ongoing compliance. These certifications are particularly important for electric valves used in hazardous locations where electrical safety requirements are more stringent due to the presence of flammable or explosive atmospheres.

Specialized Industry Certifications and Quality Assurance

Industry-specific certifications address the unique requirements of different applications and ensure electric valve suppliers can meet specialized performance and safety requirements across diverse industrial sectors.

NSF and Potable Water System Certifications

NSF International certifications ensure electric valves used in potable water systems meet strict health and safety standards for drinking water applications. NSF 61 and NSF 372 are the primary certifications for electric valves in water treatment and distribution systems. NSF 61 certification ensures that electric valve materials and coatings do not contribute harmful contaminants to drinking water, while NSF 372 addresses lead content restrictions in plumbing components. These certifications require extensive materials testing, including extraction testing to verify that electric valve components do not leach harmful substances into water supplies. The NSF certification process includes regular factory inspections and ongoing surveillance to ensure electric valve manufacturers maintain compliance with strict water safety standards. Electric valve suppliers serving municipal water systems, food processing, and beverage industries must maintain current NSF certifications to ensure their products are suitable for potable water contact. The certification also requires proper labeling and documentation to clearly identify NSF-certified electric valve products and their approved applications.

ATEX and Explosion-Proof Certifications

ATEX certification is essential for electric valves used in potentially explosive atmospheres, ensuring equipment safety in hazardous environments where flammable gases, vapors, or dust may be present. This European certification requires electric valve manufacturers to demonstrate their products meet strict explosion-prevention requirements through specialized design features and testing protocols. ATEX certification encompasses both equipment directive requirements and workplace directive compliance, ensuring electric valves are suitable for use in classified hazardous areas. The certification process includes detailed risk assessment, component testing, and quality assurance procedures specific to explosion-proof electric valve applications. Electric valve suppliers must provide ATEX certificates that clearly specify the approved hazardous area classifications, temperature ratings, and installation requirements for their certified products. This certification is particularly critical for electric valves used in offshore oil platforms, chemical processing facilities, and refineries where explosion risks are elevated. ATEX-certified electric valves incorporate specialized features such as intrinsically safe electrical circuits, explosion-proof enclosures, and flameproof designs to prevent ignition of hazardous atmospheres.

National and Regional Specific Certifications

National certifications ensure electric valve suppliers can legally market their products in specific countries and comply with local regulatory requirements. These certifications vary significantly between regions and often reflect unique safety concerns, environmental conditions, or regulatory frameworks specific to individual markets. Electric valve manufacturers serving global markets must obtain appropriate national certifications for each target market, which may include specialized testing for local environmental conditions, regulatory compliance verification, and documentation in local languages. Some countries require specific import licenses, local agent representation, or in-country testing for electric valve products, particularly for applications in critical infrastructure or safety-sensitive industries. Electric valve suppliers should provide comprehensive certification portfolios that demonstrate their ability to meet diverse national requirements without compromising product quality or performance. The certification process often includes collaboration with local certification bodies, compliance with national standards that may differ from international norms, and ongoing surveillance to maintain certification validity. Understanding these national certification requirements is essential for electric valve procurement professionals working with international suppliers or deploying valve systems across multiple countries with varying regulatory frameworks.

Quality Control and Testing Documentation Requirements

Comprehensive quality documentation distinguishes professional electric valve suppliers from those lacking proper quality management systems. Quality control certifications provide assurance that suppliers maintain consistent manufacturing standards and testing protocols throughout their production processes.

Material Certification and Traceability

Material certifications ensure electric valve components meet specified metallurgical and chemical composition requirements for their intended applications. Electric valve suppliers must provide material test certificates (MTCs) documenting the chemical composition, mechanical properties, and heat treatment details for all critical valve components. These certificates establish full material traceability from raw material sourcing through final electric valve assembly, enabling quality control and failure analysis when necessary. The material certification process includes verification of casting quality, forging integrity, and machining precision for electric valve bodies, stems, and other critical components. Electric valve manufacturers must maintain detailed records linking material certificates to specific valve serial numbers, enabling complete traceability throughout the product lifecycle. Quality material certification also includes verification of special alloy compositions, corrosion resistance properties, and high-temperature performance characteristics essential for electric valve applications in demanding environments. Suppliers should demonstrate their material sourcing procedures, incoming inspection protocols, and material handling procedures that maintain certification integrity throughout the manufacturing process.

Testing and Performance Verification Protocols

Performance testing certification validates that electric valves meet specified operational requirements under actual service conditions. Electric valve suppliers must provide comprehensive test certificates documenting pressure testing, leakage verification, and actuator performance validation for each valve assembly. The testing protocol includes hydrostatic pressure testing, pneumatic testing, and functional testing of electric actuator systems to ensure integrated performance meets specifications. Electric valve testing certification should include seat leakage testing, stem leakage verification, and electrical system functionality testing under various operating conditions. Advanced testing protocols may include vibration testing, thermal cycling, and endurance testing to verify electric valve reliability under extended service conditions. Testing documentation must include detailed test procedures, acceptance criteria, and actual test results with clear pass/fail determinations for each electric valve tested. Electric valve suppliers should maintain calibrated testing equipment with current certification to ensure test result accuracy and reliability. The testing certification process often includes third-party witness testing for critical applications, providing additional assurance of electric valve performance capabilities.

Manufacturing Quality Management Systems

Manufacturing quality certifications demonstrate that electric valve suppliers maintain systematic approaches to quality control throughout their production processes. These certifications verify that suppliers have implemented comprehensive quality management systems covering design control, manufacturing processes, inspection procedures, and corrective action systems. Electric valve manufacturers must demonstrate their quality systems include incoming material inspection, in-process quality control, and final product verification procedures that ensure consistent product quality. The quality management certification process includes regular internal audits, management reviews, and continuous improvement initiatives that enhance electric valve manufacturing capabilities. Certified suppliers must maintain detailed quality records, including non-conformance tracking, corrective action implementation, and preventive action procedures that minimize quality issues. Quality management certifications also verify that electric valve suppliers have appropriate personnel training programs, equipment calibration procedures, and document control systems that support consistent quality delivery. The certification requires demonstration of statistical process control methods, quality metrics tracking, and customer feedback integration that drives continuous improvement in electric valve manufacturing quality.

Conclusion

Selecting electric valve suppliers with proper certifications is fundamental to ensuring project success, safety compliance, and long-term operational reliability. The comprehensive certification framework covering international standards, safety requirements, and quality management systems provides the foundation for confident supplier selection decisions. Professional electric valve manufacturers distinguish themselves through their commitment to obtaining and maintaining relevant certifications that demonstrate their technical capabilities and quality commitment.

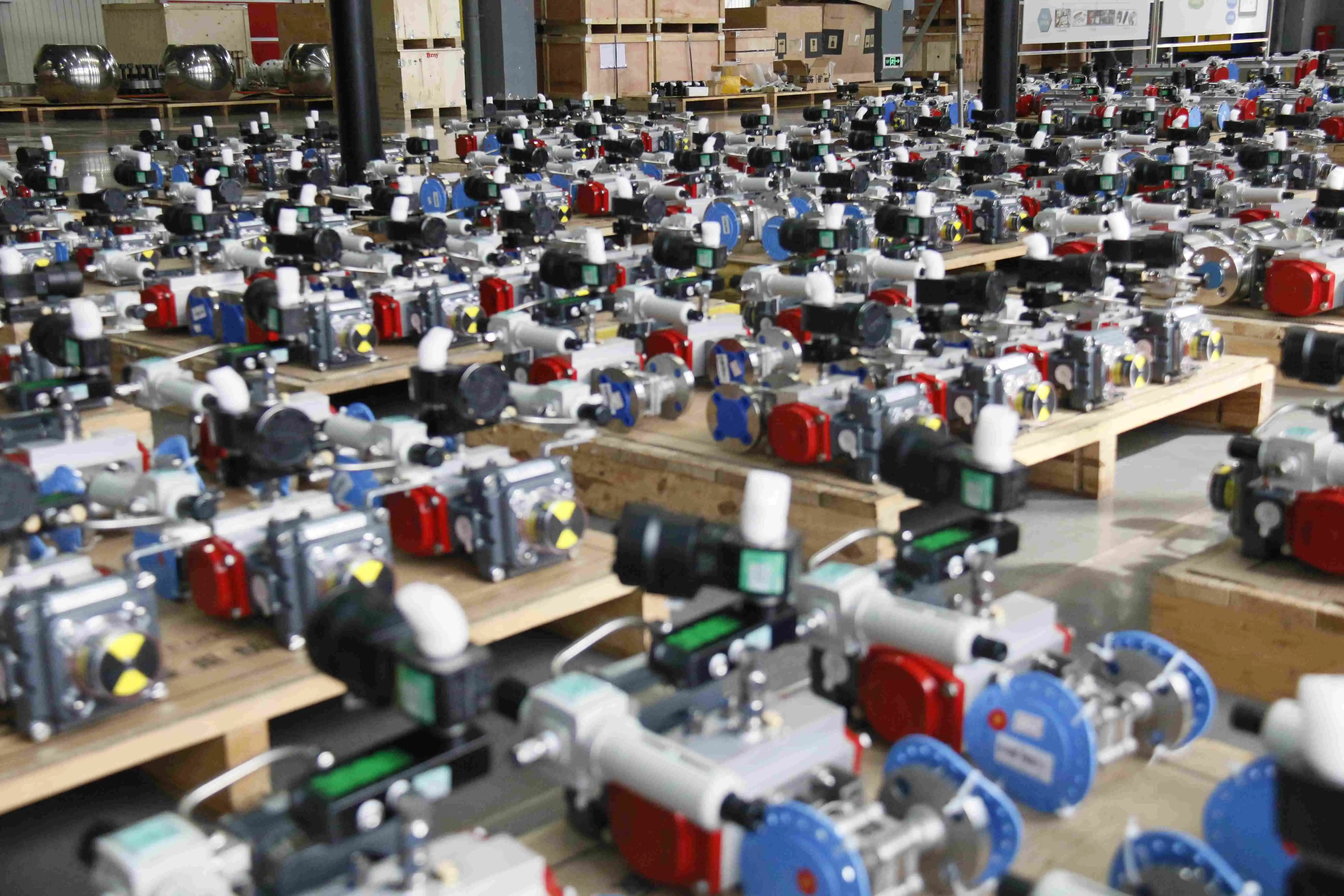

CEPAI Group Co., Ltd. stands as a premier China Electric Valve factory with comprehensive certifications including API, ISO, ASME, CE, and SIL certifications that ensure product reliability and safety compliance. As a leading China Electric Valve supplier, CEPAI maintains state-of-the-art manufacturing facilities and quality management systems that support consistent delivery of High Quality Electric Valve products. Our position as a trusted China Electric Valve manufacturer is reinforced by our extensive certification portfolio and proven track record serving major international clients. For procurement professionals seeking a reliable China Electric Valve wholesale partner, CEPAI offers competitive Electric Valve price structures without compromising quality or certification standards. Our comprehensive range of Electric Valve for sale includes customized solutions backed by full certification documentation and technical support. Contact our expert team at cepai@cepai.com to discuss your electric valve certification requirements and discover how our certified manufacturing capabilities can support your project success.

References

1. Industrial Valve Certification Standards and Requirements. American Society of Mechanical Engineers (ASME). ASME International Standards Committee.

2. API Specification for Valves and Wellhead Equipment in Petroleum Industry Applications. American Petroleum Institute (API). API Standards Development Committee.

3. International Organization for Standardization Quality Management Systems for Valve Manufacturing. International Organization for Standardization (ISO). ISO Technical Committee 153.

4. Safety Integrity Level (SIL) Certification Requirements for Process Safety Valves. International Electrotechnical Commission (IEC). IEC Functional Safety Working Group.

_1746598557316.webp)

Get professional pre-sales technical consultation and valve selection services, customized solution services.

About CEPAI