Best Suppliers for Wear-Resistant O-shaped Electric Valves

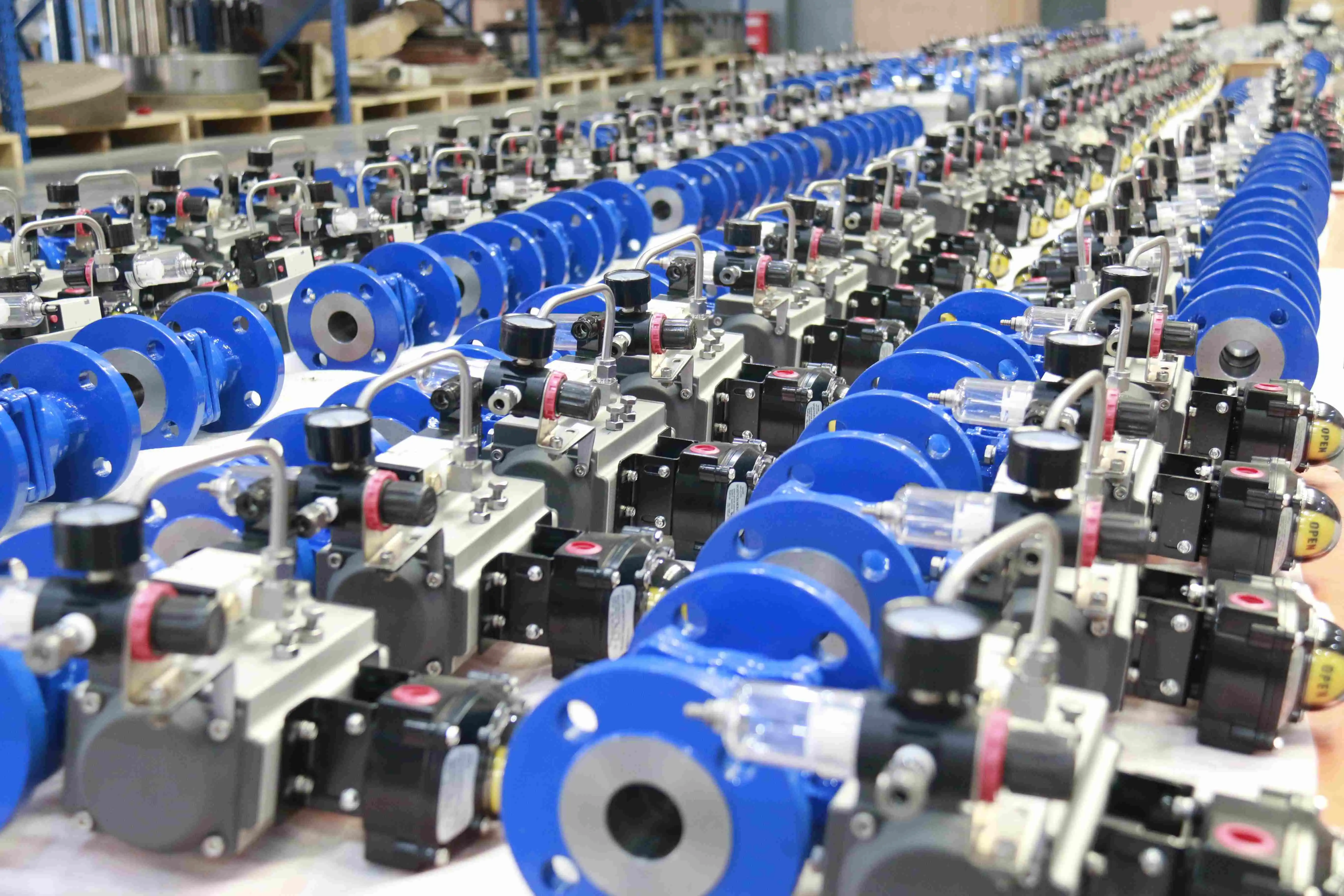

In today's rapidly evolving industrial landscape, finding reliable suppliers for wear-resistant O-shaped electric valves has become increasingly critical for maintaining operational efficiency and ensuring long-term system reliability. These specialized valve components play a vital role in controlling fluid flow across diverse industrial applications, from petrochemical processing to power generation facilities. The O-shaped Electric Valve technology represents a significant advancement in valve design, offering superior sealing performance and enhanced durability compared to traditional valve configurations. As industries continue to demand higher performance standards and longer operational lifespans from their equipment, identifying the best suppliers who can deliver both quality and innovation becomes paramount for successful project execution.

Critical Selection Criteria for O-shaped Electric Valve Suppliers

Manufacturing Excellence and Quality Assurance Standards

When evaluating suppliers for wear-resistant O-shaped Electric Valve systems, manufacturing excellence stands as the foundational requirement that determines long-term operational success. Leading suppliers must demonstrate comprehensive quality management systems that encompass every stage of production, from raw material selection through final testing and delivery. The most reliable manufacturers implement stringent quality control protocols that include material traceability, dimensional accuracy verification, and performance testing under simulated operational conditions. These companies typically maintain certifications such as ISO 9001, API standards, and industry-specific qualifications that validate their commitment to consistent quality delivery. Advanced testing facilities equipped with pressure testing chambers, material analysis equipment, and automated inspection systems enable these suppliers to guarantee that each O-shaped Electric Valve meets or exceeds specified performance parameters. The best suppliers also maintain detailed documentation throughout the manufacturing process, providing customers with complete traceability and confidence in product reliability. Furthermore, these manufacturers invest significantly in continuous improvement initiatives, regularly updating their processes and technologies to enhance product performance and manufacturing efficiency while reducing production variability and defect rates.

Technological Innovation and Research Development Capabilities

The rapidly advancing field of O-shaped Electric Valve technology demands suppliers who maintain robust research and development capabilities to address emerging industry challenges and performance requirements. Leading suppliers typically operate dedicated engineering centers staffed with experienced valve specialists, materials scientists, and automation experts who collaborate to develop next-generation valve solutions. These organizations invest substantial resources in advanced simulation software, prototype testing facilities, and collaborative research partnerships with academic institutions and industry leaders. The most innovative suppliers demonstrate their commitment through patent portfolios, published research contributions, and participation in industry standards development committees. They also maintain close relationships with end-users to understand evolving operational requirements and incorporate feedback into their product development cycles. Advanced suppliers often utilize cutting-edge technologies such as computational fluid dynamics modeling, finite element analysis, and digital twin simulations to optimize O-shaped Electric Valve performance characteristics before physical prototyping. Additionally, these companies typically offer customization capabilities that allow them to modify standard designs to meet specific application requirements, demonstrating their technical flexibility and customer-focused approach to problem-solving.

Comprehensive Technical Support and Service Infrastructure

Distinguished O-shaped Electric Valve suppliers provide comprehensive technical support services that extend far beyond basic product delivery, encompassing pre-sales consultation, installation guidance, and ongoing maintenance support throughout the valve's operational lifecycle. The most capable suppliers maintain teams of application engineers who can analyze specific operational requirements and recommend optimal valve configurations based on factors such as fluid characteristics, pressure ratings, temperature ranges, and control accuracy requirements. These organizations typically offer detailed technical documentation, including installation manuals, maintenance procedures, and troubleshooting guides that enable customers to maximize valve performance and operational lifespan. Leading suppliers also provide training programs for customer personnel, covering proper installation techniques, routine maintenance procedures, and emergency response protocols. Many advanced suppliers now offer remote monitoring capabilities and predictive maintenance services that utilize IoT sensors and data analytics to optimize valve performance and prevent unexpected failures. The best suppliers maintain global service networks with local representatives who can provide rapid response for urgent technical issues, ensuring minimal disruption to customer operations and maintaining high levels of system availability.

Industry Applications and Performance Requirements

Petrochemical and Oil Gas Processing Applications

The petrochemical and oil gas industries represent the most demanding operational environments for O-shaped Electric Valve applications, requiring exceptional durability, precise control, and reliable performance under extreme conditions. These industries typically expose valves to corrosive chemicals, high pressures, extreme temperatures, and continuous operational cycles that can quickly degrade inferior components. Leading suppliers for these applications must demonstrate extensive experience with specialized materials such as duplex stainless steels, super austenitic alloys, and exotic corrosion-resistant coatings that can withstand aggressive chemical environments. The O-shaped Electric Valve design offers particular advantages in these applications through its superior sealing characteristics and reduced leakage potential compared to traditional valve configurations. Suppliers serving these markets must maintain certifications such as API 6D, API 602, and NACE MR0175 that validate their products' suitability for critical hydrocarbon service applications. Additionally, these suppliers typically offer specialized features such as fire-safe designs, anti-static configurations, and fugitive emission controls that address specific safety and environmental requirements. The most capable suppliers maintain extensive testing capabilities that can simulate actual field conditions, including high-pressure cycling tests, corrosion resistance evaluations, and thermal shock assessments that ensure reliable performance throughout the valve's operational life.

Power Generation and Utility Infrastructure

Power generation facilities and utility infrastructure applications demand O-shaped Electric Valve solutions that can provide reliable service over extended operational periods while maintaining precise control characteristics essential for system optimization. These applications typically involve steam service, cooling water systems, fuel gas handling, and various auxiliary systems that require different valve specifications and performance characteristics. Suppliers serving this market must understand the unique requirements of power plant operations, including the need for rapid response during emergency shutdowns, precise throttling control for efficiency optimization, and long-term reliability to minimize maintenance outages. The O-shaped Electric Valve configuration offers significant advantages in these applications through its excellent flow characteristics, reduced pressure drop, and superior sealing performance that can help improve overall system efficiency. Leading suppliers for power applications typically maintain specialized coatings and materials designed for high-temperature steam service, erosion resistance, and thermal cycling capability. These suppliers also understand the critical importance of standardization and interchangeability in power plant applications, offering products that can integrate seamlessly with existing infrastructure while providing improved performance characteristics. Many advanced suppliers provide comprehensive testing documentation and performance guarantees that give power plant operators confidence in long-term reliability and operational availability.

Water Treatment and Municipal Infrastructure Systems

Municipal water treatment facilities and infrastructure systems require O-shaped Electric Valve solutions that combine reliable performance with cost-effective operation and maintenance characteristics suitable for long-term municipal service applications. These environments typically involve potable water, wastewater, and various chemical treatment processes that demand valves capable of maintaining consistent performance while minimizing maintenance requirements and operational costs. Suppliers serving municipal markets must understand the unique budget constraints and operational priorities of public utilities while delivering products that meet stringent safety and environmental standards. The O-shaped Electric Valve design provides particular benefits in these applications through its self-cleaning characteristics, reduced dead zones, and improved flow control precision that can enhance treatment process efficiency. Leading suppliers for municipal applications typically offer products manufactured from approved materials such as NSF-certified components, lead-free alloys, and environmentally safe coatings that comply with drinking water standards. These suppliers also understand the importance of standardization and parts availability for municipal operations, maintaining extensive inventory systems and providing long-term parts availability commitments. Additionally, many suppliers offer training programs specifically designed for municipal operators, covering topics such as valve operation, routine maintenance procedures, and system optimization techniques that help utilities maximize their infrastructure investments.

Supplier Evaluation Framework and Best Practices

Financial Stability and Supply Chain Reliability

Evaluating the financial stability and supply chain reliability of potential O-shaped Electric Valve suppliers represents a critical component of the selection process that directly impacts project success and long-term operational continuity. Financially stable suppliers demonstrate their ability to invest in research and development, maintain quality manufacturing processes, and provide ongoing support throughout the product lifecycle. The best suppliers maintain diversified revenue streams, strong balance sheets, and established credit relationships that enable them to weather economic downturns and market fluctuations without compromising product quality or service levels. Supply chain reliability becomes particularly important for O-shaped Electric Valve applications, as these specialized components often require specific materials, precision manufacturing processes, and quality control procedures that can be disrupted by supply chain instabilities. Leading suppliers typically maintain multiple supplier relationships for critical components, implement inventory management systems that ensure component availability, and develop contingency plans for potential supply disruptions. These organizations also demonstrate their commitment to long-term customer relationships through consistent delivery performance, transparent communication regarding potential delays or issues, and proactive problem-solving approaches when challenges arise. The most reliable suppliers often provide detailed supply chain visibility, allowing customers to understand component sourcing, manufacturing schedules, and delivery timelines that support effective project planning and execution.

Certification Standards and Regulatory Compliance

Comprehensive certification standards and regulatory compliance capabilities serve as essential indicators of supplier reliability and product quality in the O-shaped Electric Valve market, particularly for applications involving safety-critical or regulated industries. The most reputable suppliers maintain extensive certification portfolios that include international quality standards such as ISO 9001, environmental management systems like ISO 14001, and occupational health and safety certifications including ISO 45001. Industry-specific certifications such as API standards for petroleum applications, ASME codes for pressure vessel service, and CE marking for European markets demonstrate suppliers' commitment to meeting diverse regulatory requirements. Leading suppliers also maintain specialized certifications such as SIL ratings for safety instrumented systems, NACE compliance for corrosive service applications, and various national approvals for specific geographic markets. The most advanced suppliers implement comprehensive quality management systems that extend beyond basic certification requirements, incorporating continuous improvement methodologies, statistical process control, and customer feedback integration mechanisms. These organizations typically maintain detailed documentation systems that provide complete traceability from raw materials through final delivery, enabling rapid response to any quality issues or regulatory inquiries. Additionally, the best suppliers proactively monitor changing regulatory requirements and update their processes and certifications accordingly, ensuring ongoing compliance and reducing customer risk associated with regulatory changes.

Global Service Network and Local Support Capabilities

A robust global service network combined with strong local support capabilities distinguishes exceptional O-shaped Electric Valve suppliers from their competitors, particularly for customers operating multiple facilities across different geographic regions. The most capable suppliers maintain strategically located service centers, parts distribution facilities, and technical support teams that can provide rapid response to customer needs regardless of location. These organizations typically employ local engineers who understand regional regulations, operating practices, and cultural considerations that can impact project success. Advanced suppliers also maintain comprehensive spare parts inventory systems that ensure component availability when needed, reducing equipment downtime and operational disruptions. The best suppliers provide multiple communication channels including phone support, online technical resources, remote diagnostics capabilities, and field service teams that can address complex technical issues directly at customer facilities. Many leading suppliers now offer digital service platforms that provide customers with access to technical documentation, maintenance schedules, performance monitoring tools, and direct communication channels with technical experts. These platforms often include mobile applications that enable field personnel to access technical information, submit service requests, and receive real-time support during installation or maintenance activities. Furthermore, exceptional suppliers provide comprehensive training programs that can be delivered either at customer facilities or supplier training centers, ensuring that customer personnel have the knowledge and skills necessary to optimize O-shaped Electric Valve performance and reliability.

Conclusion

Selecting the best suppliers for wear-resistant O-shaped Electric Valve applications requires careful evaluation of manufacturing capabilities, technological innovation, and comprehensive support services that align with specific operational requirements. The most successful partnerships develop between customers and suppliers who demonstrate consistent quality delivery, proactive technical support, and long-term commitment to customer success across diverse industrial applications.

Ready to experience the difference that professional-grade O-shaped Electric Valve solutions can make for your operations? CEPAI Group Co., LTD. stands as your premier China O-shaped Electric Valve factory, combining advanced manufacturing capabilities with comprehensive technical expertise to deliver superior valve solutions. As a leading China O-shaped Electric Valve supplier and established China O-shaped Electric Valve manufacturer, we offer competitive China O-shaped Electric Valve wholesale pricing alongside exceptional quality assurance. Our High Quality O-shaped Electric Valve products are available for immediate delivery, with transparent O-shaped Electric Valve price structures and flexible O-shaped Electric Valve for sale options designed to meet your specific requirements. Contact our technical specialists today at cepai@cepai.com to discuss your project requirements and discover how our proven expertise can optimize your system performance while reducing long-term operational costs.

References

1. "Industrial Valve Technology and Applications in Process Control Systems" - Johnson, M.R., Smith, P.L., and Chen, W.H., Journal of Process Engineering Technology

2. "Advanced Materials and Design Considerations for High-Performance Electric Actuated Valves" - Rodriguez, A.C., Thompson, K.J., and Liu, S.Y., International Valve Manufacturing Review

3. "Reliability Engineering and Maintenance Optimization for Critical Flow Control Systems" - Anderson, D.M., Brown, R.K., and Zhang, H.L., Industrial Equipment Reliability Quarterly

4. "Global Valve Market Analysis and Supplier Performance Evaluation Framework" - Williams, J.P., Davis, C.R., and Kumar, V.S., International Industrial Equipment Trade Journal

Get professional pre-sales technical consultation and valve selection services, customized solution services.

About CEPAI