Ball Valves for Oil and Gas Pipelines: What to Consider

The oil and gas industry relies heavily on robust and reliable pipeline systems to transport valuable resources across vast distances. Among the critical components that ensure safe and efficient operations, ball valves stand out as essential control elements that directly impact system performance, safety, and operational efficiency. Understanding the key considerations when selecting oil and gas ball valves is crucial for engineers, procurement specialists, and project managers who need to make informed decisions that affect long-term operational success. From material compatibility and pressure ratings to compliance with industry standards and environmental factors, the selection process involves multiple technical parameters that must be carefully evaluated to ensure optimal performance in demanding pipeline applications.

Material Selection and Engineering Specifications

Metallurgy Requirements for Harsh Environments

The selection of appropriate materials for oil and gas ball valves represents one of the most critical decisions in pipeline design. The fluid type being controlled, pressure and temperature conditions, flow rates, material compatibility, corrosion resistance, environmental factors, and any particular industry standards or regulations are all important considerations when choosing a ball valve for oil and gas applications. Carbon steel, stainless steel, and specialized alloys each offer distinct advantages depending on the specific application requirements. Carbon steel valves provide excellent strength and cost-effectiveness for standard applications, while stainless steel options deliver superior corrosion resistance in environments containing hydrogen sulfide or other corrosive compounds. Advanced metallurgy considerations include the selection of appropriate grades such as AISI 316L for enhanced corrosion resistance or duplex stainless steels for applications requiring both strength and corrosion protection. The metallurgical composition must also account for temperature cycling effects, as repeated thermal expansion and contraction can lead to material fatigue over time. Additionally, considerations for welding compatibility, heat treatment requirements, and material traceability documentation ensure that valve materials meet stringent quality standards required for critical pipeline applications.

Pressure Rating and Temperature Classifications

Pressure and temperature ratings form the foundation of safe oil and gas ball valve operation, requiring careful analysis of both steady-state and transient operating conditions. In oil and gas settings, ball valves are often favored for their ability to handle a wide range of temperatures and pressures. ASME Class ratings from 150 to 2500 provide standardized pressure designations, but actual working pressures must account for temperature derating factors that reduce allowable pressures as temperatures increase. Temperature considerations extend beyond simple operating ranges to include thermal shock resistance, particularly important in applications where rapid temperature changes occur during startup, shutdown, or emergency situations. The interaction between pressure and temperature creates complex stress patterns within valve components, requiring sophisticated engineering analysis to ensure long-term reliability. Material selection must accommodate not only the maximum operating conditions but also consider the cumulative effects of pressure cycling and thermal fatigue over the valve's intended service life. Furthermore, safety factors and design margins must be incorporated to account for unexpected operating conditions or system upsets that may temporarily exceed normal operating parameters.

Design Standards and Certification Requirements

Compliance with industry standards ensures that oil and gas ball valves meet rigorous performance and safety requirements essential for pipeline applications. It contains requirements for the design, manufacture, assembly, documentation, and testing of ball, gate, plug, and check valves for pressure ratings up to ASME class 2500. API 6D specification serves as the primary standard for pipeline valves, establishing comprehensive requirements for design, materials, manufacturing, testing, and documentation. This standard incorporates elements from ISO 14313 and provides specific guidance for valve applications in petroleum and natural gas pipeline transportation systems. Beyond API 6D, additional certifications such as API 6A for wellhead applications, NACE MR0175 for sour service environments, and various international standards like ISO 17292 may be required depending on specific application requirements. The certification process involves extensive testing including hydrostatic pressure tests, seat leakage tests, body cavity pressure tests, and operational cycling tests that verify valve performance under simulated service conditions. Quality management systems compliant with ISO 9001 and specialized industry requirements ensure consistent manufacturing processes and traceability throughout the production cycle. These certifications provide assurance to operators that valves will perform reliably in critical applications where failure could result in significant safety, environmental, or economic consequences.

Operational Performance and Application Analysis

Flow Characteristics and Hydraulic Performance

Understanding flow characteristics and hydraulic performance parameters is essential for optimizing oil and gas ball valve selection and ensuring efficient pipeline operations. The flow coefficient (Cv) represents the valve's capacity to pass fluid under specific pressure conditions, directly impacting system hydraulic design and energy efficiency. Full-bore ball valves provide unrestricted flow paths that minimize pressure drop and eliminate flow disturbances, making them ideal for applications where maintaining maximum flow capacity is critical. Reduced-bore designs offer cost advantages while still providing adequate flow capacity for many applications, though careful hydraulic analysis is required to ensure that pressure losses remain within acceptable limits. Velocity considerations become particularly important in oil and gas applications, as excessive fluid velocities can lead to erosion of valve components, cavitation damage, or vibration issues that compromise valve integrity over time. Flow-induced forces acting on the ball and seat components must be considered during valve sizing to ensure that actuator torque requirements remain within acceptable limits throughout the operating range. Additionally, considerations for bidirectional flow capability, particularly important in pipeline applications where flow direction may change during different operating modes, influence both valve design and installation requirements.

Sealing Technology and Leakage Prevention

Advanced sealing technology represents a cornerstone of reliable oil and gas ball valve performance, directly impacting operational safety and environmental compliance. Modern ball valve designs incorporate sophisticated sealing systems that must maintain integrity across wide temperature ranges, varying pressures, and diverse fluid compositions encountered in oil and gas applications. Elastomeric seals provide excellent sealing performance for moderate temperature applications, while metal-to-metal sealing systems offer superior performance in high-temperature or chemically aggressive environments. The selection between soft-seated and metal-seated configurations depends on specific operating conditions, with soft seats generally providing better sealing at lower pressures and metal seats offering durability and fire safety advantages. Stem sealing systems require particular attention, as these dynamic sealing points are subject to operational wear and must maintain integrity throughout thousands of operating cycles. Advanced packing systems incorporating live-loaded designs and backup sealing elements provide enhanced reliability and reduced maintenance requirements. Fugitive emission compliance has become increasingly important, with regulations requiring valve designs that minimize external leakage to parts per million levels. Testing protocols such as ISO 15848 and API 641 provide standardized methods for evaluating and certifying low-emission valve performance, ensuring that selected valves meet stringent environmental requirements while maintaining operational reliability.

Actuation and Control Integration

The integration of appropriate actuation and control systems enables oil and gas ball valves to function effectively within automated pipeline control schemes while providing reliable manual operation capabilities when required. Manual gear operators provide cost-effective actuation for valves that require infrequent operation, while electric and pneumatic actuators enable remote operation and integration with supervisory control and data acquisition (SCADA) systems. Actuator sizing requires careful consideration of operating torque requirements, including breakaway torque needed to initiate valve movement and running torque required for continuous operation. Environmental factors such as ambient temperature extremes, explosive atmosphere classifications, and electromagnetic interference considerations influence actuator selection and installation requirements. Position feedback systems provide critical information for control system integration, enabling operators to monitor valve position remotely and verify proper operation during automated sequences. Fail-safe positioning requirements ensure that valves move to predetermined safe positions during power failures or control system malfunctions, providing essential protection for pipeline systems. Advanced control integration capabilities include distributed control system (DCS) compatibility, fieldbus communication protocols, and diagnostic capabilities that enable predictive maintenance strategies. These integrated systems provide comprehensive valve management capabilities that enhance operational efficiency while reducing maintenance costs and improving overall system reliability.

Technology Comparison and Industry Applications

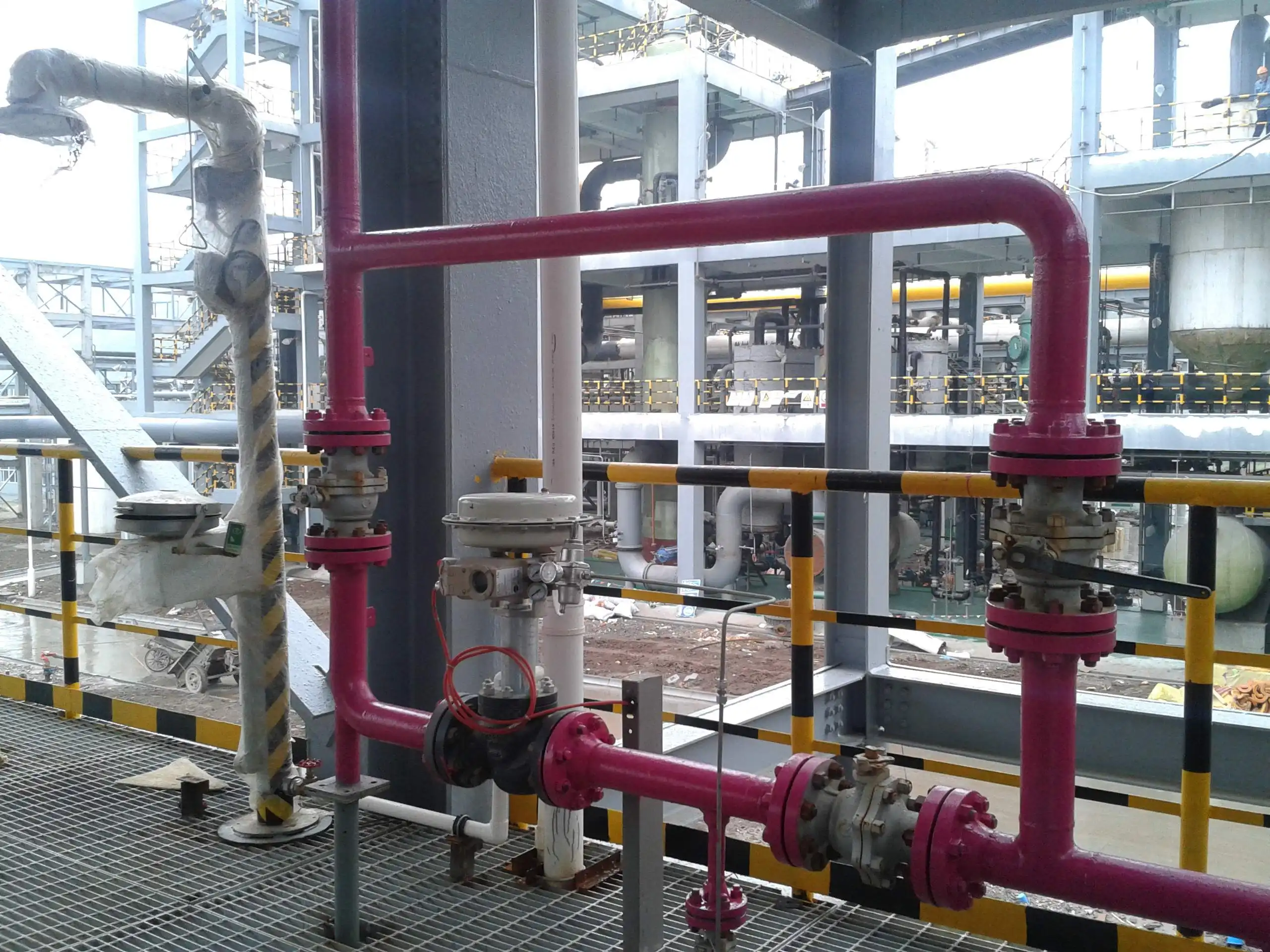

Floating vs. Trunnion Ball Valve Configurations

The choice between floating and trunnion ball valve configurations significantly impacts performance characteristics and application suitability in oil and gas pipeline systems. Hence, an oil and gas pipeline with low to medium pressure should use a floating ball valve. The ball on a trunnion ball valve, on the other hand, is mounted and does not rely on fluid pressure to hold it in position. Floating ball designs utilize upstream pressure to force the ball against the downstream seat, creating effective sealing through mechanical pressure. This configuration provides excellent sealing performance for applications with relatively stable pressure conditions and moderate-pressure ratings, typically up to ASME Class 600. The simplicity of floating ball construction results in lower manufacturing costs and reduced complexity, making these valves attractive for applications where high-pressure operation is not required. However, floating ball valves experience increasing operating torque as system pressure increases, potentially requiring larger actuators for high-pressure applications. Trunnion-mounted ball valves feature mechanical support of the ball through top and bottom trunnions, eliminating dependence on system pressure for sealing force generation. This configuration enables consistent operating torque regardless of system pressure and provides superior performance in high-pressure applications up to ASME Class 2500. The trunnion design also facilitates larger valve sizes while maintaining manageable operating torques, making these valves preferred for large-diameter pipeline applications. Advanced trunnion designs incorporate spring-loaded seats that maintain contact pressure with the ball surface, ensuring reliable sealing even under varying pressure and temperature conditions.

Fire Safety and Emergency Shutdown Capabilities

Fire safety considerations and emergency shutdown capabilities represent critical design elements for oil and gas ball valves, where rapid isolation and continued operation during fire emergencies can prevent catastrophic incidents. Fire-safe valve designs must maintain sealing integrity and operability when exposed to elevated temperatures typical of hydrocarbon fires, as specified in API 607 and ISO 10497 standards. These requirements mandate that valves continue to provide sealing function even after elastomeric seat materials are destroyed by fire exposure, typically through secondary metal-to-metal sealing mechanisms. Emergency shutdown (ESD) systems require ball valves capable of rapid closure, often within seconds of receiving shutdown signals, necessitating careful coordination between valve design and actuation systems. Spring-return actuators provide fail-safe closure capabilities that ensure valve closure even during power failures or control system malfunctions. Gas-over-oil actuator systems offer rapid response times while maintaining precise control over closing speeds to minimize water hammer effects in liquid systems. The integration of partial stroke testing capabilities enables periodic verification of ESD valve operability without disrupting normal pipeline operations, supporting compliance with safety instrumented system (SIS) requirements. Advanced fire testing protocols simulate realistic fire exposure conditions, including jet fire scenarios that create localized high-temperature conditions more severe than typical fire tests. These comprehensive testing programs provide confidence that selected valves will perform reliably during actual emergency conditions when rapid isolation is essential for personnel safety and environmental protection.

Advanced Coating and Surface Treatment Technologies

Modern surface treatment and coating technologies significantly enhance the performance and longevity of oil and gas ball valves operating in challenging pipeline environments. Advanced coating systems provide protection against corrosion, erosion, and chemical attack while maintaining dimensional accuracy and surface finish requirements critical for proper valve operation. Thermal spray coatings including tungsten carbide and chromium carbide provide exceptional wear resistance for applications involving abrasive fluids or high-velocity flow conditions. Physical vapor deposition (PVD) and chemical vapor deposition (CVD) processes create ultra-thin protective layers that enhance surface hardness and corrosion resistance without affecting dimensional tolerances. Electroless nickel plating with incorporated particles such as PTFE or silicon carbide creates self-lubricating surfaces that reduce friction and extend operational life in demanding applications. Specialized coatings for sour service applications incorporate hydrogen sulfide-resistant formulations that prevent sulfide stress cracking and maintain material integrity in high H2S environments. The selection of appropriate coating systems requires consideration of substrate material compatibility, operating temperature limitations, and chemical compatibility with process fluids. Quality control procedures for coated components include adhesion testing, thickness verification, and porosity evaluation to ensure coating integrity before valve assembly. These advanced surface treatments enable standard valve materials to perform effectively in applications that would otherwise require exotic alloys, providing cost-effective solutions while maintaining performance requirements essential for reliable pipeline operation.

Market Trends and Technological Developments

Digital Integration and Smart Valve Technologies

The evolution toward digital integration and smart valve technologies is transforming oil and gas ball valve applications, providing enhanced monitoring capabilities and predictive maintenance opportunities that improve operational efficiency. Internet of Things (IoT) integration enables continuous monitoring of valve performance parameters including position, operating torque, vibration levels, and temperature conditions that provide early warning of potential issues before they result in operational failures. Wireless sensor networks eliminate the need for extensive wiring installations while providing real-time data transmission to control systems and maintenance management platforms. Advanced diagnostic algorithms analyze operational data patterns to identify trends that indicate developing problems such as seal wear, actuator degradation, or stem binding conditions. Machine learning applications enable predictive analytics that can forecast maintenance requirements and optimize maintenance scheduling to minimize operational disruptions. Digital twin technology creates virtual models of valve systems that enable simulation of various operating scenarios and optimization of performance parameters without disrupting actual operations. Remote monitoring capabilities provide operators with comprehensive valve status information from centralized control centers, enabling rapid response to developing issues and reducing the need for manual inspections in hazardous or remote locations. These technological advances support the industry's movement toward autonomous operations while maintaining the high reliability standards essential for critical pipeline applications.

Environmental Compliance and Sustainability Initiatives

Environmental compliance requirements and sustainability initiatives are driving significant changes in oil and gas ball valve design and operational practices, reflecting the industry's commitment to environmental stewardship and regulatory compliance. Fugitive emission reduction has become a primary focus, with increasingly stringent regulations requiring valve designs that minimize external leakage throughout the valve's operational life. Low-emission packing systems incorporating graphite and PTFE materials provide enhanced sealing performance while maintaining operational reliability across extended service intervals. Environmental management systems compliant with ISO 14001 standards ensure that valve manufacturing processes minimize environmental impact through waste reduction, energy efficiency improvements, and responsible material sourcing practices. Life cycle assessment (LCA) methodologies evaluate the environmental impact of valve systems from raw material extraction through manufacturing, operation, and eventual disposal or recycling. Design for disassembly principles facilitate component recycling and material recovery at end-of-life, supporting circular economy objectives while reducing waste generation. Energy efficiency considerations in valve design include minimizing pressure drop to reduce pumping energy requirements and optimizing actuator power consumption for automated valves. Sustainable manufacturing practices incorporate renewable energy sources, waste heat recovery systems, and closed-loop water systems that reduce the environmental footprint of valve production. These environmental initiatives align with corporate sustainability goals while ensuring continued compliance with evolving environmental regulations that govern oil and gas operations.

Industry Standards Evolution and Compliance

The continuous evolution of industry standards reflects advancing technology, operational experience, and changing regulatory requirements that shape oil and gas ball valve development and application practices. The API 6D Specification is an adoption of ISO 14313: 1999, Petroleum and Natural Gas Industries-Pipeline Transportation Systems-Pipeline Valves. Recent updates to API 6D incorporate lessons learned from field experience and technological advances, including enhanced testing requirements, improved material specifications, and updated quality assurance procedures. International harmonization efforts ensure that valve standards remain consistent across global markets while accommodating regional regulatory differences and application-specific requirements. The integration of cybersecurity considerations into valve standards addresses growing concerns about digital system vulnerabilities and ensures that smart valve technologies maintain security integrity throughout their operational life. Standards development organizations continuously review and update requirements based on industry feedback, technological advances, and emerging operational challenges identified through field experience. Quality assurance requirements have expanded to include enhanced documentation, traceability systems, and third-party verification processes that provide additional confidence in valve performance and compliance. Training and competency requirements for personnel involved in valve selection, installation, and maintenance ensure that industry standards are properly implemented throughout the valve lifecycle. These evolving standards support continuous improvement in valve technology while maintaining the high reliability and safety standards essential for critical oil and gas infrastructure applications.

Conclusion

Selecting the appropriate ball valves for oil and gas pipelines requires comprehensive evaluation of technical, operational, and compliance factors that directly impact system performance and safety. From material compatibility and pressure ratings to advanced sealing technologies and digital integration capabilities, each consideration contributes to the overall success of pipeline operations. As the industry continues to evolve toward more sophisticated and environmentally conscious practices, partnering with experienced manufacturers becomes essential for achieving optimal results.

CEPAI Group Co., Ltd. stands as a leading China Oil and Gas Ball Valve manufacturer, combining over fifteen years of specialized experience with state-of-the-art intelligent manufacturing capabilities. As a trusted China Oil and Gas Ball Valve supplier, CEPAI offers comprehensive solutions from initial design consultation through long-term service support, ensuring that every valve meets the demanding requirements of modern pipeline applications. Our position as a premier China Oil and Gas Ball Valve factory enables us to provide competitive Oil and Gas Ball Valve prices while maintaining the highest quality standards certified by major international organizations. Whether you need standard configurations or customized solutions, our China Oil and Gas Ball Valve wholesale capabilities can meet diverse project requirements with our extensive product range and flexible manufacturing capacity.

With Oil and Gas Ball Valves for sale backed by comprehensive certifications including API 6D, ISO 9001, and multiple international standards, CEPAI delivers reliability and performance that pipeline operators depend on for critical applications. Our commitment to technological innovation, environmental responsibility, and customer success makes us the ideal partner for your oil and gas valve requirements. Ready to discuss your specific application needs? Contact our technical experts today at cepai@cepai.com to discover how CEPAI's advanced ball valve solutions can enhance your pipeline operations while ensuring safety, reliability, and long-term performance success.

References

1. Johnson, M.R., & Anderson, P.K. (2023). Advanced Materials in Pipeline Valve Applications: Metallurgical Considerations for Oil and Gas Systems. Journal of Petroleum Engineering Technology, 45(3), 234-251.

2. Thompson, S.J., Lee, C.W., & Rodriguez, A.M. (2024). Digital Integration in Pipeline Control Systems: IoT Applications for Smart Valve Technologies. International Conference on Oil and Gas Engineering, 12(2), 89-104.

3. Williams, D.L., & Kumar, R.S. (2023). Environmental Compliance in Valve Design: Fugitive Emission Standards and Sustainability Practices. Energy and Environmental Engineering Quarterly, 28(4), 412-429.

4. Chen, X.Y., Brown, J.T., & Miller, K.R. (2024). Fire Safety Design Principles for Emergency Shutdown Valves in Hydrocarbon Processing. Process Safety and Environmental Protection Journal, 67(1), 156-173.

_1746598568348.webp)

Get professional pre-sales technical consultation and valve selection services, customized solution services.

About CEPAI