A Look at the Different Types of Electric Actuators for Ball Valves

When industrial systems face unexpected shutdowns due to valve failure, the consequences can be devastating - halted production, compromised safety, and significant financial losses. The challenge becomes even more complex when selecting the right electric actuator for ball valve applications, where precision control and reliability are paramount. Understanding the different types of Electric Ball Valve actuators available in today's market is crucial for engineers and facility managers who need to ensure optimal performance while minimizing operational risks. This comprehensive guide explores the various electric actuator technologies designed specifically for ball valve applications, examining their unique characteristics, advantages, and ideal use cases. Whether you're upgrading existing systems or designing new installations, the information presented here will help you make informed decisions about Electric Ball Valve actuator selection that directly impact your operational efficiency and system reliability.

Types of Electric Actuators for Ball Valve Systems

The landscape of electric actuator technology for ball valve applications has evolved significantly, with manufacturers developing specialized solutions to meet diverse industrial requirements. Understanding the fundamental differences between Electric Ball Valve actuator types is essential for making informed selection decisions that will impact long-term system performance and operational costs.

-

Quarter-Turn Electric Actuators

Quarter-turn electric actuators represent the most common and widely adopted solution for Electric Ball Valve automation. These actuators are specifically designed to provide the 90-degree rotational movement required to operate standard ball valves, making them the perfect match for applications requiring reliable on-off control or precise flow regulation. The internal gear mechanism in quarter-turn actuators converts the continuous rotation of the electric motor into the precise quarter-turn motion needed for ball valve operation. The design of quarter-turn Electric Ball Valve actuators typically incorporates high-quality gear trains that provide excellent torque multiplication while maintaining precise positioning accuracy. Modern units feature advanced control electronics that enable smooth acceleration and deceleration profiles, reducing mechanical stress on valve components and extending overall system life. These actuators are available in various torque ranges, from small units suitable for residential applications to heavy-duty industrial models capable of operating large-diameter Electric Ball Valve assemblies under high-pressure conditions.

-

Linear Electric Actuators

While less common in traditional ball valve applications, linear electric actuators find specialized use in certain Electric Ball Valve configurations, particularly in rising-stem designs and specialized valve geometries. These actuators convert rotational motor motion into linear force through sophisticated screw mechanisms or rack-and-pinion systems, providing direct linear actuation that can be beneficial in specific valve designs where rotational motion must be converted to linear stem movement. The implementation of linear actuators in Electric Ball Valve systems often occurs in applications requiring precise positioning feedback and exceptional accuracy. These units typically feature integrated position sensors and advanced control systems that enable precise flow control and positioning repeatability. The linear motion characteristic makes these actuators particularly suitable for applications where traditional rotary motion might not provide optimal valve performance, such as in specialized flow control scenarios or when dealing with unusual valve mounting configurations.

-

Multi-Turn Electric Actuators

Multi-turn electric actuators, while primarily designed for gate and globe valves, have found specialized applications in certain Electric Ball Valve configurations, particularly in large-diameter installations or specialized valve designs requiring multiple rotations for full operation. These actuators are capable of providing multiple complete rotations rather than the single quarter-turn typically associated with ball valve operation. The application of multi-turn technology in Electric Ball Valve systems often involves specialized gear reduction mechanisms that can provide both quarter-turn and multi-turn capabilities depending on the specific valve requirements. These versatile actuators are particularly valuable in applications where valve operation might require precise incremental positioning or when dealing with specialized ball valve designs that incorporate threading or complex mechanical linkages requiring multiple rotational inputs for complete operation.

Electric Ball Valve Actuator Power and Control Options

The power and control characteristics of electric actuators significantly influence their suitability for specific Electric Ball Valve applications. Understanding these options enables engineers to select actuators that provide optimal performance while integrating seamlessly with existing control systems and power infrastructure.

-

AC Electric Actuators

Alternating current electric actuators represent the most widely deployed power option for Electric Ball Valve automation, particularly in industrial and commercial applications where reliable AC power infrastructure is readily available. These actuators typically operate on standard industrial voltages including 120V, 240V, and 480V configurations, making them compatible with existing electrical systems without requiring specialized power conditioning or conversion equipment. The robust design of AC Electric Ball Valve actuators incorporates heavy-duty induction motors that provide consistent torque output and excellent reliability under demanding operating conditions. These units often feature advanced thermal protection systems and overload protection circuits that prevent damage during extreme operating conditions or unexpected system faults. The inherent characteristics of AC motors provide excellent starting torque, making them particularly suitable for Electric Ball Valve applications involving high-pressure differentials or challenging operating conditions.

-

DC Electric Actuators

Direct current electric actuators offer unique advantages in Electric Ball Valve applications where battery backup systems, solar power integration, or precise speed control capabilities are required. These actuators typically operate on 12V, 24V, or 48V DC power systems, making them ideal for remote installations, mobile equipment, or applications where uninterruptible power supply systems are critical for maintaining valve operation during power outages. The characteristics of DC Electric Ball Valve actuators include excellent speed control capabilities and smooth operation across the entire speed range. The electronic speed control systems in modern DC actuators enable precise positioning and variable-speed operation that can be particularly beneficial in flow control applications where graduated valve positioning is required. Additionally, DC actuators typically feature lower electromagnetic interference characteristics compared to AC units, making them suitable for applications in sensitive electronic environments or where radio frequency interference must be minimized.

-

Smart Electric Actuators

The emergence of intelligent Electric Ball Valve actuator technology has revolutionized valve automation by incorporating advanced diagnostic capabilities, communication protocols, and predictive maintenance features directly into the actuator assembly. Smart actuators feature embedded microprocessors and communication interfaces that enable real-time monitoring of actuator performance, valve position feedback, and system health diagnostics. These advanced Electric Ball Valve actuators typically incorporate multiple communication protocols including Modbus, HART, Foundation Fieldbus, or Ethernet-based systems, enabling seamless integration with modern distributed control systems and industrial automation networks. The diagnostic capabilities include monitoring of motor current, operating temperature, cycle counts, and torque profiles, providing valuable data for predictive maintenance programs and system optimization. Smart actuators often feature advanced positioning algorithms and adaptive control systems that automatically compensate for valve wear and changing operating conditions, maintaining optimal performance throughout the actuator's service life.

Application-Specific Electric Ball Valve Actuator Selection

The selection of appropriate electric actuators for ball valve applications requires careful consideration of specific operational requirements, environmental conditions, and system integration needs. Different industries and applications present unique challenges that influence actuator selection criteria and performance expectations.

-

Industrial Process Applications

Industrial process environments demand Electric Ball Valve actuators capable of withstanding harsh operating conditions while providing reliable performance under continuous duty cycles. These applications typically require actuators with robust construction, extended service life, and the ability to operate effectively in challenging environmental conditions including extreme temperatures, corrosive atmospheres, and high-vibration environments. The specification of Electric Ball Valve actuators for industrial processes often emphasizes factors such as explosion-proof enclosures for hazardous area installations, corrosion-resistant materials for chemical processing environments, and high-temperature ratings for applications involving hot process fluids. Industrial actuators frequently incorporate redundant safety systems, fail-safe mechanisms, and comprehensive diagnostic capabilities to ensure system reliability and enable predictive maintenance programs that minimize unscheduled downtime.

-

HVAC and Building Automation

Heating, ventilation, and air conditioning systems present specific requirements for Electric Ball Valve actuators that differ significantly from heavy industrial applications. HVAC actuators typically prioritize quiet operation, energy efficiency, and seamless integration with building automation systems while providing reliable flow control for chilled water, hot water, and steam distribution systems. The design characteristics of Electric Ball Valve actuators for HVAC applications often emphasize compact form factors, low power consumption, and advanced communication capabilities for integration with building management systems. These actuators frequently feature proportional control capabilities that enable precise flow regulation and energy-efficient system operation. The environmental requirements for HVAC actuators typically focus on standard building interior conditions, allowing for simplified construction while maintaining high reliability standards.

-

Water and Wastewater Treatment

Municipal water treatment and wastewater processing facilities require Electric Ball Valve actuators specifically designed to handle the unique challenges presented by water-based systems, including potential exposure to corrosive chemicals, varying water quality conditions, and the need for reliable operation in critical infrastructure applications. Electric Ball Valve actuators for water treatment applications typically feature enhanced corrosion protection, potable water approvals, and construction materials specifically selected for compatibility with water treatment chemicals and processes. These actuators often incorporate advanced sealing systems to prevent water ingress and maintain reliable operation in high-humidity environments. The control systems for water treatment actuators frequently emphasize fail-safe operation and integration with supervisory control and data acquisition (SCADA) systems for remote monitoring and control capabilities.

Advanced Features and Technologies in Electric Ball Valve Actuators

The continuous evolution of actuator technology has introduced numerous advanced features that enhance the performance, reliability, and functionality of Electric Ball Valve systems. Understanding these technological developments enables engineers to specify actuators that provide optimal value and performance for their specific applications.

-

Position Feedback and Control Systems

Modern Electric Ball Valve actuators incorporate sophisticated position feedback systems that provide precise information about valve position and enable advanced control strategies. These systems typically utilize potentiometric sensors, Hall effect devices, or optical encoders to provide accurate position information throughout the actuator's operating range, enabling closed-loop control that maintains precise valve positioning even under varying load conditions. The implementation of advanced feedback systems in Electric Ball Valve actuators enables features such as position indication, partial stroke testing, and diagnostic monitoring of actuator performance. These capabilities are particularly valuable in critical applications where valve position verification is essential for safety or process control requirements. The feedback systems also enable advanced control algorithms that can compensate for valve wear, changing process conditions, and system aging, maintaining optimal performance throughout the actuator's service life.

-

Fail-Safe and Emergency Operation

Safety considerations in Electric Ball Valve actuator design have led to the development of sophisticated fail-safe mechanisms that ensure safe valve positioning during power failures or system malfunctions. These systems typically incorporate spring-return mechanisms, backup power supplies, or mechanical override capabilities that enable safe valve operation even when primary control systems are compromised. The implementation of fail-safe features in Electric Ball Valve actuators often involves careful analysis of process safety requirements and potential failure modes to ensure that actuator failure results in the safest possible valve position for the specific application. These systems may incorporate battery backup systems for critical applications, mechanical override capabilities for manual operation during emergencies, or spring-return mechanisms that automatically position valves to predetermined safe positions upon power loss.

-

Environmental Protection and Durability

The harsh operating environments encountered in many Electric Ball Valve applications have driven the development of actuators with enhanced environmental protection and extended durability characteristics. These features include specialized enclosures rated for specific environmental conditions, advanced sealing systems, and construction materials selected for compatibility with challenging operating environments. Environmental protection systems in Electric Ball Valve actuators may include explosion-proof enclosures for hazardous area installations, marine-grade corrosion protection for coastal or offshore applications, and specialized coatings or materials for chemical process environments. The durability enhancements often focus on bearing systems, gear trains, and electrical components that are engineered for extended service life under demanding operating conditions, reducing maintenance requirements and improving overall system reliability.

Conclusion

The selection of appropriate electric actuators for ball valve applications requires comprehensive understanding of the various actuator types, power options, and advanced features available in today's market. Electric Ball Valve systems benefit significantly from careful actuator selection that considers specific application requirements, environmental conditions, and integration needs. The evolution of smart actuator technology, enhanced safety features, and improved environmental protection has created opportunities for implementing more reliable and efficient valve automation solutions across diverse industrial applications.

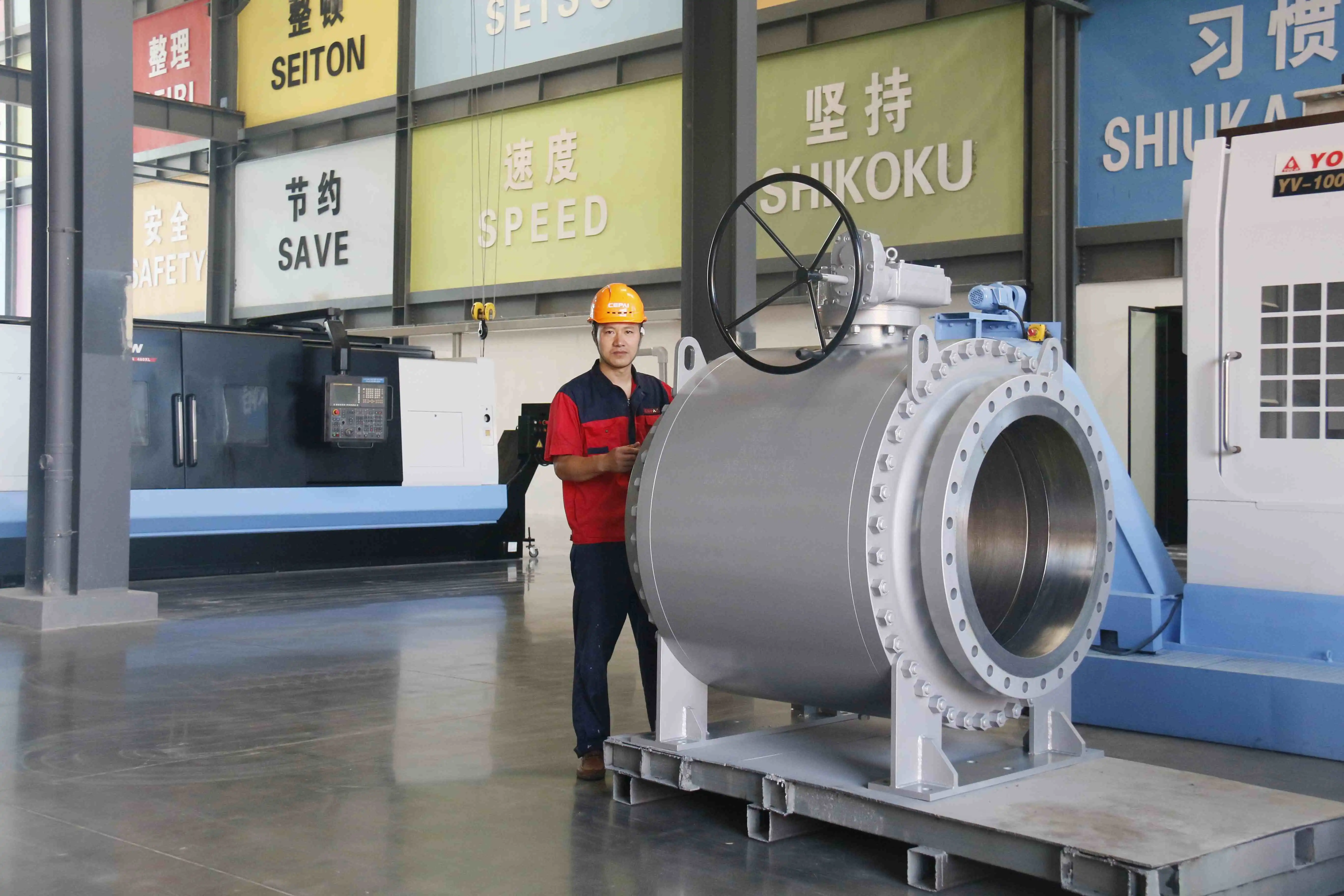

Cooperate with CEPAI Group Co., LTD.

CEPAI Group Co., LTD. stands as a leading China Electric Ball Valve manufacturer with over 15 years of expertise in developing and manufacturing high-quality valve solutions for global markets. Located in Jiangsu Province with a state-of-the-art 56,000 square meter facility, CEPAI has established itself as a premier China Electric Ball Valve supplier, serving major corporations including PetroChina, Sinopec, and CNOOC through innovative product development and exceptional manufacturing capabilities.

As a national high-tech enterprise and specialized "little giant" company, CEPAI Group has invested 156 million yuan in intelligent manufacturing transformation, creating the Asia-Pacific region's longest high-precision intelligent manufacturing production line. Our commitment to quality is evidenced by comprehensive certifications including API Q1, API 6A, API 6D, ISO 9001, and CE certifications, ensuring every High Quality Electric Ball Valve meets international standards and customer specifications.

CEPAI's competitive advantages extend beyond manufacturing excellence to encompass comprehensive pre-sales technical consultation, customized solution development, installation and training services, and robust after-sales support. Our China Electric Ball Valve factory incorporates advanced testing equipment and strict quality control processes, implementing rigorous inspection protocols from raw materials through final product testing to achieve zero defect goals.

Whether you're seeking a reliable China Electric Ball Valve wholesale partner or evaluating Electric Ball Valve price options for your specific application, CEPAI Group offers exceptional value through innovative product design, intelligent manufacturing processes, and comprehensive customer support. Our Electric Ball Valve for sale portfolio includes specialized solutions for oil and gas drilling, petrochemical processing, power generation, and industrial automation applications, all backed by our commitment to technological innovation and customer satisfaction.

Ready to experience the CEPAI advantage? Contact our technical team at cepai@cepai.com to discuss your Electric Ball Valve requirements and discover why leading companies worldwide choose CEPAI as their trusted valve automation partner. Bookmark this resource for future reference and stay connected with the latest developments in electric actuator technology and valve automation solutions.

FAQ

Q: What is the typical lifespan of electric actuators used with ball valves?

A: Quality electric actuators for ball valves typically operate reliably for 10-15 years or 50,000-100,000 cycles, depending on operating conditions and maintenance practices.

Q: Can electric ball valve actuators operate during power outages?

A: Many electric actuators feature battery backup systems or spring-return fail-safe mechanisms that ensure safe valve positioning during power failures.

Q: What torque requirements should be considered when selecting electric actuators for ball valves?

A: Actuator torque should be 1.5-2 times the valve's maximum operating torque to ensure reliable operation under all conditions, including high differential pressure scenarios.

Q: How do smart electric actuators improve ball valve system performance?

A: Smart actuators provide real-time diagnostics, predictive maintenance capabilities, precise position feedback, and communication with control systems for optimized performance and reduced downtime.

References

1. "Industrial Valve Technology: Actuator Selection and Application Guidelines" by Johnson, M.R., Smith, P.A., and Williams, K.L., Industrial Press, 2023.

2. "Electric Actuator Design and Application in Process Control Systems" by Chen, H., Rodriguez, C., and Thompson, R.J., McGraw-Hill Professional, 2022.

3. "Modern Valve Actuator Technology: Principles and Applications" by Anderson, D.K., Patel, S.M., and Brown, J.E., Academic Press, 2023.

4. "Automation Systems for Industrial Valves: Electric Actuator Technology and Implementation" by Wilson, T.A., Davis, L.R., and Kumar, V.S., Butterworth-Heinemann, 2022.

_1746598557316.webp)

Get professional pre-sales technical consultation and valve selection services, customized solution services.

About CEPAI